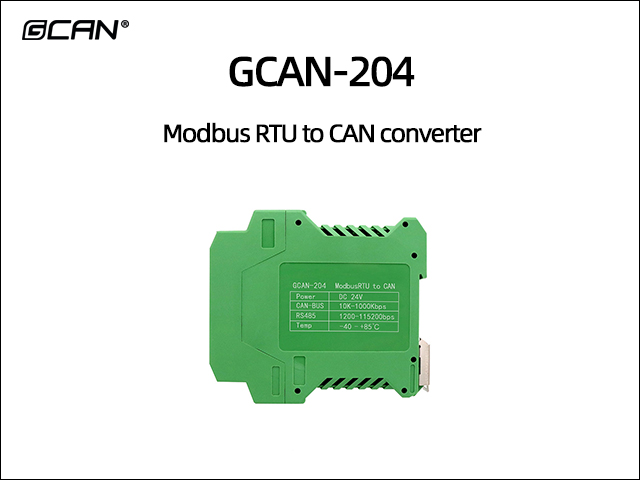

GCAN-204 Modbus RTU to CAN converter

- Brand:

- GCAN

- Model:

- GCAN-204

- Application:

- ● Existing serial communication devices are connected to the CAN bus network; ● PLC equipment connected to CAN bus network communication; ● Modbus RTU network and CAN network communication; ● Gateway bridge between CAN bus and serial bus; ● Industrial site network data monitoring; ● CAN teaching application remote communication; ● CAN industrial automation control system; ● Low speed CAN network data collection and analysis; ● Intelligent building control data broadcasting system and other CAN bus application systems.

-

1. Equipment Introduction

The GCAN-204 module is an industrial grade Modbus RTU to CAN module that integrates one standard serial port and one standard CAN bus interface. The serial bus end of the GCAN-204 module has integrated the Modbus RTU protocol. With the GCAN-204 module, users can connect devices that originally used the serial bus for communication (Modbus RTU protocol) to the CAN bus communication interface without changing the original hardware structure. This allows devices that use the Modbus RTU protocol for communication to quickly connect to the CAN bus and form nodes in the CAN bus network.

When the GCAN-204 module reads data from Modbus, it will real-time load the data received on the CAN bus into the cache and wait for Modbus commands to read. After receiving the Modbus read command, the module will convert the specified CAN data and send it to the Modbus bus; When the module receives a Modbus data transmission command, it will directly process the Modbus data and send it to the CAN bus.

The GCAN-204 module is a key tool for industrial bus transformation and interconnection of multiple bus devices. At the same time, this module has the characteristics of small size, plug and play, and is also the best choice for existing system integration. The various bus interfaces of GCAN-204 are integrated with isolation protection modules to prevent damage to the module caused by instantaneous overvoltage and overcurrent. The use of DIN rail fixation makes it easier to integrate into various control cabinets.

2. Equipment parameters

● Modbus slave support function codes: 03H, 04H, 06H, 16H;

● The standard serial port adopts a 2-wire RS485 interface;

● The serial port baud rate supports a range of 600bps~115200bps and can be configured through software;

● CAN bus supports CAN2.0A and CAN2.0B frame formats and complies with the ISO/DIS 11898 specification;

● The CAN bus communication baud rate can be programmed between 5Kbps and 1Mbps;

● The CAN bus interface adopts electrical isolation, and the insulation voltage of the isolation module is DC 1500V;

● Maximum conversion data flow: 400 frames per second (measured at the maximum serial port baud rate);

● Use 9~24V DC power supply (recommended 24V 20mA);

● RS485 and CAN interfaces use terminal wiring methods;

● Use specialized configuration software to configure the working mode and all parameters;

● Non volatile memory stores configuration parameters and automatically calls the latest parameters after each power on;

● Can be installed on DIN card rails;

● Working temperature range: -40 ℃~+85 ℃;

3. Application Fields

● Existing serial communication devices are connected to the CAN bus network;

● PLC equipment connected to CAN bus network communication;

● Modbus RTU network and CAN network communication;

● Gateway bridge between CAN bus and serial bus;

● Industrial site network data monitoring;

● CAN teaching application remote communication;

● CAN industrial automation control system;

● Low speed CAN network data collection and analysis;

● Intelligent building control data broadcasting system and other CAN bus application systems.

Welcome to inquire and learn more

-

- ● Existing serial communication devices are connected to the CAN bus network;

● PLC equipment connected to CAN bus network communication;

● Modbus RTU network and CAN network communication;

● Gateway bridge between CAN bus and serial bus;

● Industrial site network data monitoring;

● CAN teaching application remote communication;

● CAN industrial automation control system;

● Low speed CAN network data collection and analysis;

● Intelligent building control data broadcasting system and other CAN bus application systems.

- Packing

Standard package:Carton

Delivery Time

2~5 days after receipt of your payment by air express

After-sale service

GCAN provide one year free after-sales warranty,lifetime free software and technical support.