Are you interested in OBD product development?

In modern cars, you can control the car's start, flameout, and wiper sliding through the dashboard or the buttons around the seat. The lights are turned off, and the more expensive and high-end cars can also automatically switch the doors. The roof is free to change, etc., all of this is inseparable from the hard work of countless generations of car developers. In recent years, the breakthroughs of this kind of research are all in one place called OBD interface. Today, we will Talk about some topics about OBD and find out some information about OBD product development that engineers are interested in.

Before we talk about OBD product development, let's take a look at what is OBD. The so-called OBD is the abbreviation of On-Board Diagnostics. The main function of this system is to monitor the running condition of the car engine and the working state of the exhaust gas after-treatment system at any time. Once it is found that it may cause excessive discharge, it will immediately issue a warning. When the system fails, the fault light or check engine warning light is on, and the OBD system will store the fault information in the memory. The standard diagnostic instrument and diagnostic interface can read the relevant information in the form of fault code. According to the fault code, the maintenance personnel can quickly and accurately determine the nature and location of the fault. In general, OBD is an important tool for car maintenance personnel to diagnose car-related problems.

Let's talk about the corresponding OBD product development tools. OBD engineers with the corresponding basic knowledge know that some OBD interfaces of automobiles have gateways, and it is impossible to directly detect or download corresponding data, and it is not realistic to ask the vehicle manufacturer for the corresponding source data. Then you need to make a broken connection inside the car and bypass the gateway, so that you can smoothly read the CAN bus data inside the car, and it is recommended that the professional operate.

After connecting to the car CAN bus using the OBD product development tool, connect the other end to the computer, open the corresponding software such as ECANTools, and select the baud rate to receive the data on the car bus. It should be noted here that each car manufacturer has its own proprietary agreement. Therefore, the OBD product development tools receive the original data in the bus, and can not directly get the specific meaning. The specific meaning of the data needs to be analyzed by the engineers themselves. In addition to the proprietary protocol, the software incorporates the analysis of some common protocols, which can be seen in specific meanings. Open the OBDII interface of ECANTools, you can see the general data of the 15765 protocol, such as engine speed, oil temperature and water temperature.

USBCAN-OBD model OBD product development tool

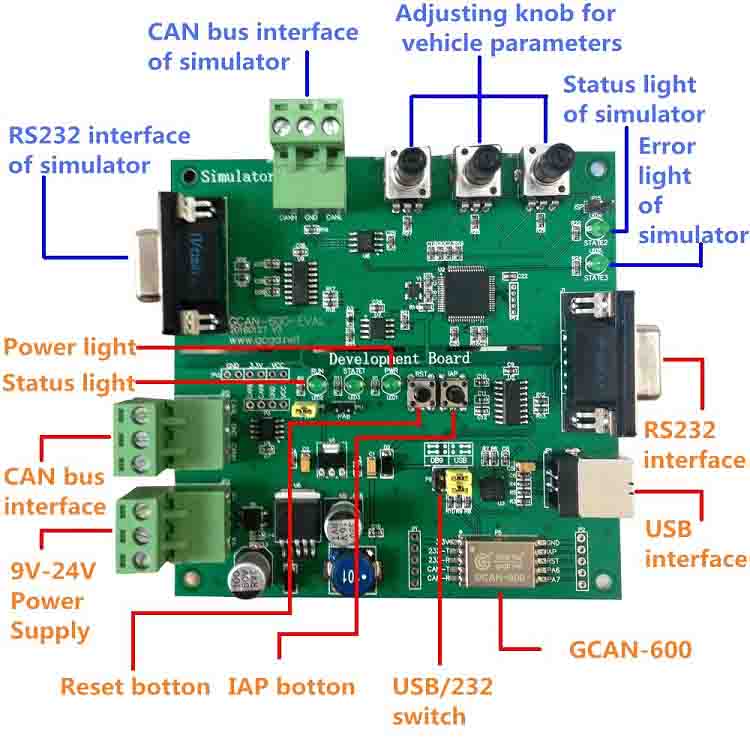

In order to meet the needs of the majority of automotive OBD developers, GCAN has specially developed the USBCAN-OBD OBD product development tool, which is designed for automotive electronics development or automotive fault diagnosis users, using USBCAN-OBD OBD product development tools, PC It can be quickly connected to the CAN-bus network in the car OBD interface through the USB interface, so that the PC can constitute the CAN-bus network control node for data processing and data acquisition in the CAN-bus network of the car. If you just want to simulate the general protocol of the car, you can purchase our GCAN-600-V3 development board, which can be used to simulate the data conforming to the 15765 protocol through the adjustment of the knob. The development board also has a rich interface for development and use.

If you would like to know more about Shenyang Guangcheng Technology's USBCAN-OBD OBD product development tool, please click on the link below to learn more: http://www1.gcanbox.com/fsd/qcdzcpy/152.html

Before we talk about OBD product development, let's take a look at what is OBD. The so-called OBD is the abbreviation of On-Board Diagnostics. The main function of this system is to monitor the running condition of the car engine and the working state of the exhaust gas after-treatment system at any time. Once it is found that it may cause excessive discharge, it will immediately issue a warning. When the system fails, the fault light or check engine warning light is on, and the OBD system will store the fault information in the memory. The standard diagnostic instrument and diagnostic interface can read the relevant information in the form of fault code. According to the fault code, the maintenance personnel can quickly and accurately determine the nature and location of the fault. In general, OBD is an important tool for car maintenance personnel to diagnose car-related problems.

Let's talk about the corresponding OBD product development tools. OBD engineers with the corresponding basic knowledge know that some OBD interfaces of automobiles have gateways, and it is impossible to directly detect or download corresponding data, and it is not realistic to ask the vehicle manufacturer for the corresponding source data. Then you need to make a broken connection inside the car and bypass the gateway, so that you can smoothly read the CAN bus data inside the car, and it is recommended that the professional operate.

After connecting to the car CAN bus using the OBD product development tool, connect the other end to the computer, open the corresponding software such as ECANTools, and select the baud rate to receive the data on the car bus. It should be noted here that each car manufacturer has its own proprietary agreement. Therefore, the OBD product development tools receive the original data in the bus, and can not directly get the specific meaning. The specific meaning of the data needs to be analyzed by the engineers themselves. In addition to the proprietary protocol, the software incorporates the analysis of some common protocols, which can be seen in specific meanings. Open the OBDII interface of ECANTools, you can see the general data of the 15765 protocol, such as engine speed, oil temperature and water temperature.

USBCAN-OBD model OBD product development tool

If you would like to know more about Shenyang Guangcheng Technology's USBCAN-OBD OBD product development tool, please click on the link below to learn more: http://www1.gcanbox.com/fsd/qcdzcpy/152.html