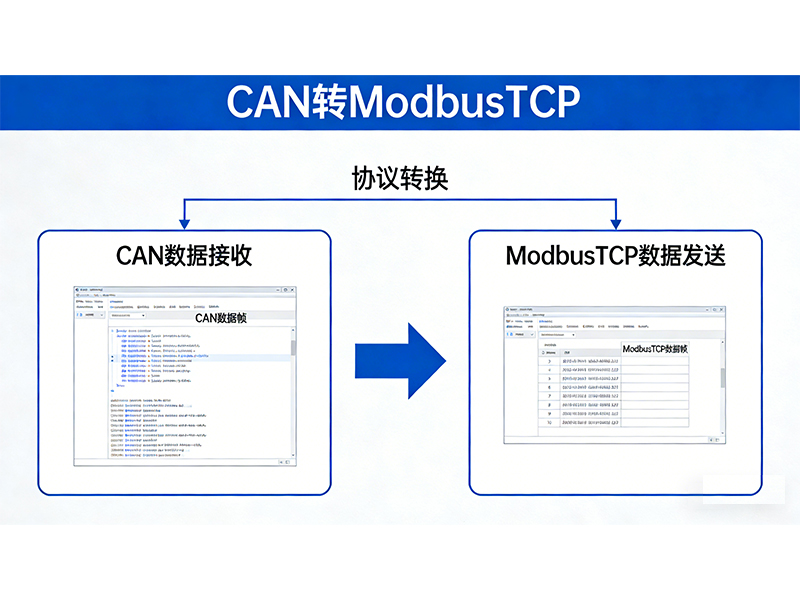

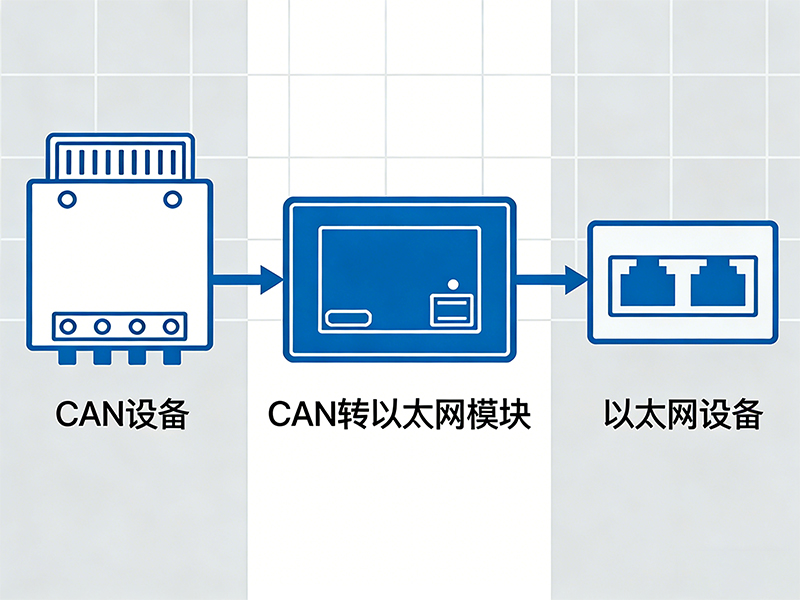

Solution to the problem of CAN to Modbus TCP conversion

1.设备上电后,网口/CAN口指示灯异常

1. After the device is powered on, the network/CAN port indicator light is abnormal

核心原因:供电故障、接口接触不良。解决:检查DC24V供电正负极及稳定性;更换屏蔽网线、CAN接头并拧紧;异常则排查硬件损坏。

Core reasons: power supply failure, poor interface contact. Solution: Check the positive and negative poles and stability of the DC24V power supply; Replace the shielded network cable and CAN connector and tighten them; If there is an abnormality, check for hardware damage.

2.电脑/PLC无法ping通设备

2. The computer/PLC cannot ping the device

核心原因:IP网段不符、网络配置错误。解决:确保电脑与设备IP在同一网段(如192.168.1.xxx),子网掩码统一为255.255.255.0;关闭防火墙,用直连网线测试。

Core reasons: IP network segment mismatch, network configuration error. Solution: Ensure that the computer and device IP are in the same network segment (such as 192.168.1. xxx), and the subnet mask is uniformly 255.255.255.0; Turn off the firewall and test with a direct wired cable.

3.ModbusTCP主站提示通讯超时

3. Modbus TCP main station prompts communication timeout

核心原因:从站地址、端口不匹配。解决:核对从站地址(默认多为1)、502端口,主从端保持一致;缩短超时时间至500-2000ms。

Core reason: The slave address and port do not match. Solution: Verify the slave address (usually 1 by default) and port 502, ensuring consistency between the master and slave ends; Shorten the timeout to 500-2000ms.

4.CAN侧无数据,TCP侧有连接

4. There is no data on the CAN side, but there is a connection on the TCP side

核心原因:CAN参数不匹配、终端电阻缺失。解决:统一CAN波特率(250K/500Kbps)和ID格式;总线首尾接120Ω终端电阻,测CAN_H与CAN_L电压(2.5-3.5V)。

Core reasons: CAN parameter mismatch, missing terminal resistance. Solution: Unified CAN baud rate (250K/500Kbps) and ID format; Connect a 120 Ω terminal resistor at the beginning and end of the bus, and measure the voltage (2.5-3.5V) of CAN_S and CAN_L.

5.数据交互乱码/数值错误

5. Data exchange garbled/numerical errors

核心原因:数据格式、地址映射错误。解决:统一数据格式(INT/FLOAT)和字节序;核对CAN数据与Modbus保持寄存器(4x区)映射地址,避免重叠。

Core reason: Data format and address mapping errors. Solution: Unified data format (INT/FLOAT) and byte order; Verify the mapping address between CAN data and Modbus hold registers (4x area) to avoid overlap.

6.设备运行中频繁掉线

6. Frequent disconnections during device operation

核心原因:供电不稳、电磁干扰。解决:加装稳压电源,CAN总线用双绞屏蔽线并单端接地;升级设备最新固件,修复稳定性BUG。

Core reasons: unstable power supply, electromagnetic interference. Solution: Install a voltage regulator power supply, use twisted pair shielded wires for the CAN bus, and ground it at one end; Upgrade the latest firmware of the device and fix stability bugs.

7.多设备组网,部分无法通讯

7. Multiple devices networking, some unable to communicate

核心原因:IP冲突、交换机过载。解决:分配唯一静态IP;选用工业级交换机,开启风暴抑制功能,避免网络瘫痪。

Core reasons: IP conflict, switch overload. Solution: Assign a unique static IP address; use industrial grade switches and enable storm suppression function to avoid network paralysis.

8.CAN侧部分从站无数据上传

8. There is no data upload from the CAN side station

核心原因:CAN ID冲突、滤波错误。解决:确保所有CAN从站ID唯一;关闭错误滤波功能,单独测试故障从站是否上线。

Core reasons: CAN ID conflict, filtering error. Solution: Ensure that all CAN slave IDs are unique; Turn off the error filtering function and test separately whether the faulty slave station is online.

9.部分寄存器数值不变/跳变

9. Some register values remain unchanged/jump

核心原因:刷新频率不匹配、总线丢包。解决:调整数据刷新频率,主站读取频率不高于CAN上传频率;缩短总线距离,必要时加中继器。

Core reasons: mismatched refresh rate and bus packet loss. Solution: Adjust the data refresh frequency to ensure that the main station's reading frequency is not higher than the CAN upload frequency; Shorten the bus distance and add repeaters if necessary.

10.恢复出厂后无法重新配置

10. Unable to reconfigure after factory reset

核心原因:软件不兼容、操作错误。解决:安装厂家原装配置软件;恢复出厂后断电重启,配置完成后保存并重启设备生效。

Core reasons: software incompatibility, operational errors. Solution: Install the manufacturer's original configuration software; After factory restoration, power off and restart the device. Once the configuration is complete, save and restart the device to take effect.

通用技巧:先排查硬件供电、接线,再检查软件配置;单设备测试排除组网干扰,借助调试工具快速定位故障。

General technique: First check the hardware power supply and wiring, then check the software configuration; Single device testing eliminates network interference and quickly locates faults with the help of debugging tools.

如果您的项目需要用到CAN转ModbusTCP设备,可以加微信13019325660或前往沈阳广成科技官网具体咨询。

If your project requires CAN to Modbus TCP devices, you can add WeChat 13019325660 or visit the official website of Shenyang Guangcheng Technology for specific consultation.

Last:The 10 most common problems and solutions for converting CAN

Next:No more