Who can use Profinet IO in their work?

Who can use Profinet IO in their work?

1. Automotive production line engineer

In the complete vehicle assembly line, Profinet IO enables high-speed interconnection between robots, conveyor lines, tightening machines, and inspection equipment. Engineers utilize it to achieve real-time synchronous control among devices, such as multi-robot collaborative operations at the body welding station. Additionally, it supports rapid collection and tracing of production data, ensuring efficient and flexible production on the assembly line.

2. Intelligent Warehouse System Integrator

When building automated three-dimensional warehouses, integrators utilize Profinet IO to connect equipment such as stackers, AGVs, conveyors, and barcode readers, enabling centralized control and precise scheduling of storage devices. This meets the efficient flow requirements for goods in and out of storage, and also facilitates easy integration with WMS warehouse management systems, enhancing the intelligence level of the storage system.

3. Operation and maintenance personnel for food and beverage production lines

The filling, labeling, and sorting production lines in the food and beverage industry have high requirements for equipment operational stability and cleanliness. The anti-interference capability and rapid diagnostic function of Profinet IO can assist operation and maintenance personnel in real-time monitoring of the operational status of motors, sensors, and valves, quickly locating fault points, reducing production line downtime, and ensuring production continuity.

4. Photovoltaic cell production technician

The processes of slicing, coating, and testing of photovoltaic cells require the collaborative work of multiple high-precision devices. The real-time communication feature of Profinet IO ensures the synchronization of actions among devices in each process. Technicians use it to adjust device parameters and collect production process data, achieving refined control over cell production and improving product yield.

5. Intelligent Building Equipment Engineer

In intelligent building projects, engineers utilize Profinet IO to integrate central air conditioning units, fresh air systems, lighting systems, security monitoring, and other equipment, enabling centralized monitoring and linkage control of building equipment. For instance, it can automatically adjust the operating state of air conditioning based on indoor temperature and humidity, while reducing equipment energy consumption and enhancing the efficiency of intelligent building management.

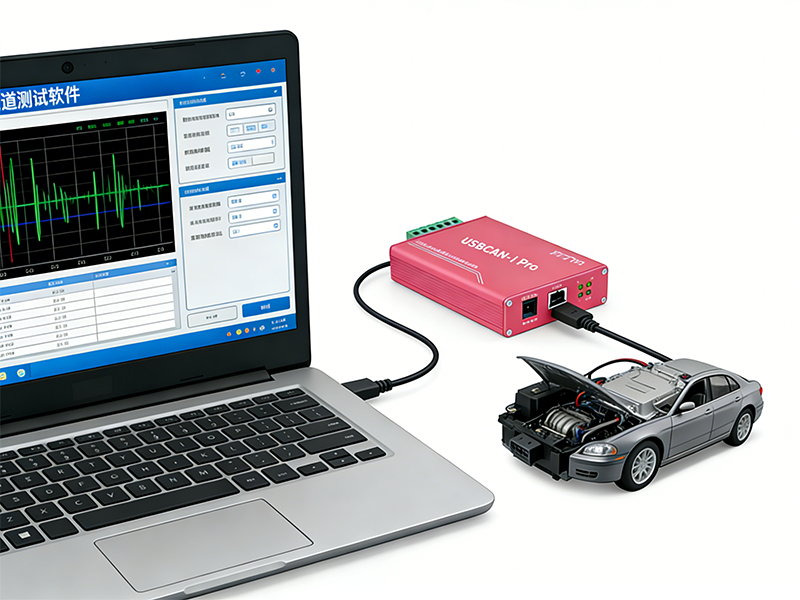

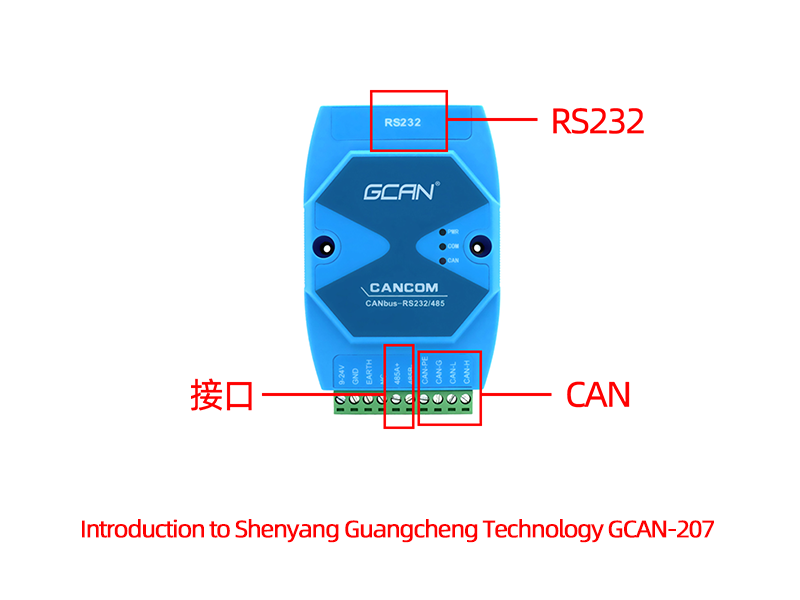

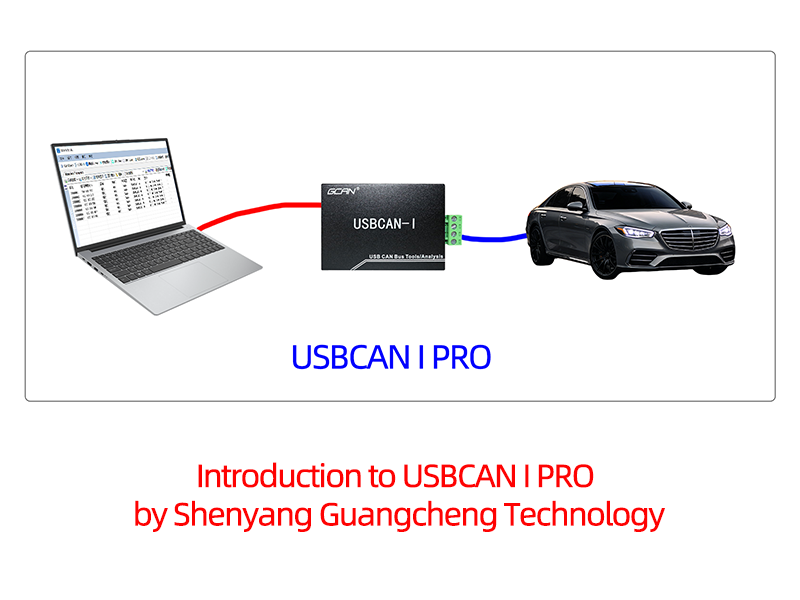

If you have a need to use Profinet IO devices in your project, you can reach out to me on WeChat at 13019325660, or visit the official website of Shenyang Guangcheng Technology for specific inquiries. We welcome your visit.

1. Automotive production line engineer

In the complete vehicle assembly line, Profinet IO enables high-speed interconnection between robots, conveyor lines, tightening machines, and inspection equipment. Engineers utilize it to achieve real-time synchronous control among devices, such as multi-robot collaborative operations at the body welding station. Additionally, it supports rapid collection and tracing of production data, ensuring efficient and flexible production on the assembly line.

2. Intelligent Warehouse System Integrator

When building automated three-dimensional warehouses, integrators utilize Profinet IO to connect equipment such as stackers, AGVs, conveyors, and barcode readers, enabling centralized control and precise scheduling of storage devices. This meets the efficient flow requirements for goods in and out of storage, and also facilitates easy integration with WMS warehouse management systems, enhancing the intelligence level of the storage system.

3. Operation and maintenance personnel for food and beverage production lines

The filling, labeling, and sorting production lines in the food and beverage industry have high requirements for equipment operational stability and cleanliness. The anti-interference capability and rapid diagnostic function of Profinet IO can assist operation and maintenance personnel in real-time monitoring of the operational status of motors, sensors, and valves, quickly locating fault points, reducing production line downtime, and ensuring production continuity.

4. Photovoltaic cell production technician

The processes of slicing, coating, and testing of photovoltaic cells require the collaborative work of multiple high-precision devices. The real-time communication feature of Profinet IO ensures the synchronization of actions among devices in each process. Technicians use it to adjust device parameters and collect production process data, achieving refined control over cell production and improving product yield.

5. Intelligent Building Equipment Engineer

In intelligent building projects, engineers utilize Profinet IO to integrate central air conditioning units, fresh air systems, lighting systems, security monitoring, and other equipment, enabling centralized monitoring and linkage control of building equipment. For instance, it can automatically adjust the operating state of air conditioning based on indoor temperature and humidity, while reducing equipment energy consumption and enhancing the efficiency of intelligent building management.

If you have a need to use Profinet IO devices in your project, you can reach out to me on WeChat at 13019325660, or visit the official website of Shenyang Guangcheng Technology for specific inquiries. We welcome your visit.