What are the common application scenarios for CAN-to-Etherne

1. Data monitoring of industrial production lines

In automobile and electronic assembly production lines, devices such as field PLCs, sensors, and actuators are networked through the CAN bus. CAN-to-Ethernet devices convert CAN bus data into Ethernet protocol and upload it to the MES system, enabling real-time collection and archiving of data such as production takt time, equipment utilization rate, and product yield. This supports remote monitoring of production line status, timely warning of equipment failures, and enhances production efficiency.

2. Operation and maintenance of charging piles for new energy vehicles

The internal controller of the charging pile, electricity meter, battery detection module, etc. exchange data through the CAN bus. The CAN-to-Ethernet device can upload information such as charging pile operating parameters, charging status, and fault codes to the cloud operation and maintenance platform. Operation and maintenance personnel can remotely view the device status and troubleshoot faults without on-site inspection, reducing operation and maintenance costs and ensuring stable operation of the charging pile.

3. Integrated control of intelligent building equipment

In intelligent buildings, devices such as elevator operation controllers, central air conditioning units, and lighting systems often utilize CAN bus communication. CAN-to-Ethernet devices serve as a bridge between the field bus and the building automation system, enabling monitoring of elevator operation status, automatic adjustment of air conditioning temperature, and zoned control of lighting. Additionally, they upload energy consumption data of the devices to the management platform, thereby facilitating energy conservation and consumption reduction in the building.

4. State monitoring of rail transit vehicles

The core components of rail transit vehicles, such as the traction system, braking system, and door control unit, transmit operational data through the CAN bus. The CAN-to-Ethernet device transmits key data such as vehicle speed, brake pressure, and motor temperature to the ground monitoring center in real time, ensuring traffic safety. Additionally, it supports automatic recording of fault data, providing accurate basis for vehicle maintenance and shortening maintenance cycles.

5. Intelligent control of agricultural IoT

In smart agricultural greenhouses, devices such as temperature and humidity sensors, soil moisture monitors, and integrated water and fertilizer dispensers are networked through a CAN bus. CAN-to-Ethernet devices upload collected environmental data and device operation data to the agricultural IoT platform, allowing farmers to remotely monitor the greenhouse environment and automatically control operations such as water and fertilizer irrigation, roller shutter lifting, and more. This enables precise planting and improves the yield and quality of agricultural products.

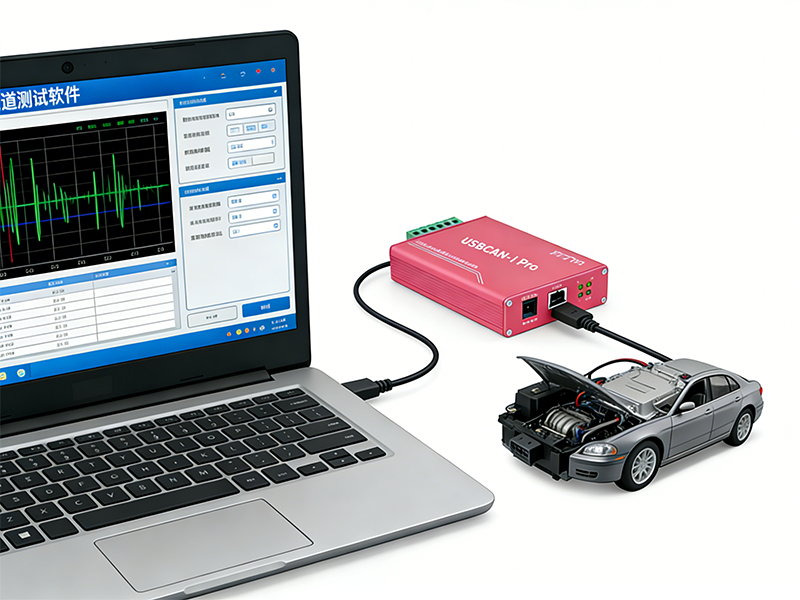

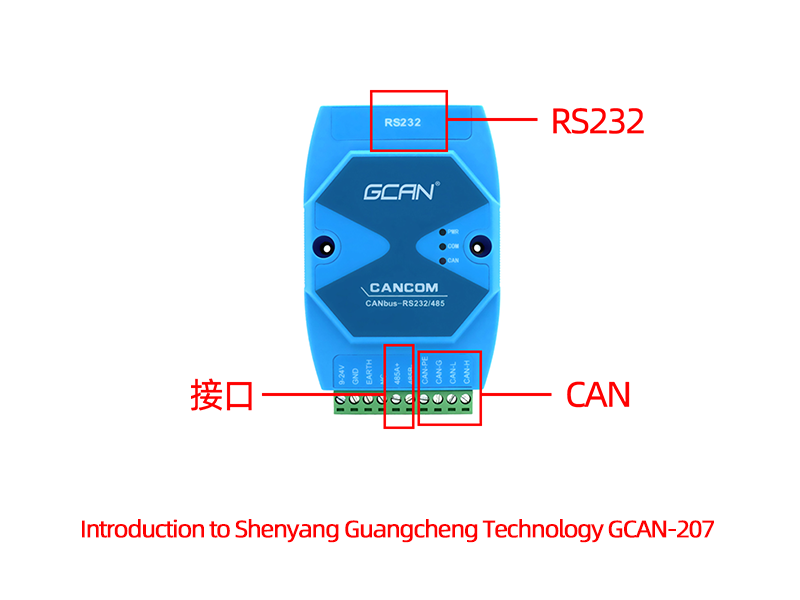

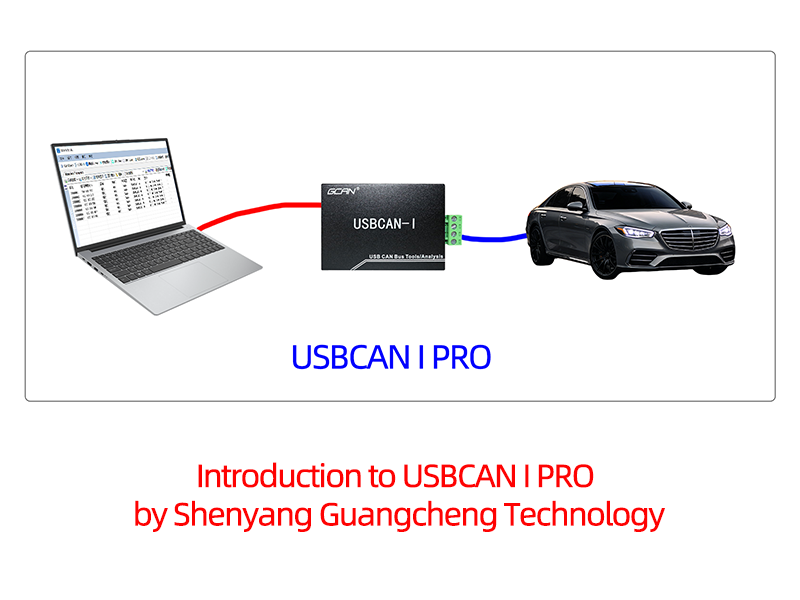

To meet the demand for CAN-to-Ethernet devices, Shenyang Guangcheng Technology has launched the GCAN-212 device, which features a compact structure and easy installation, with dedicated technical guidance for use. You can reach me on WeChat at 13019325660 for more details, and I welcome you to visit.

In automobile and electronic assembly production lines, devices such as field PLCs, sensors, and actuators are networked through the CAN bus. CAN-to-Ethernet devices convert CAN bus data into Ethernet protocol and upload it to the MES system, enabling real-time collection and archiving of data such as production takt time, equipment utilization rate, and product yield. This supports remote monitoring of production line status, timely warning of equipment failures, and enhances production efficiency.

2. Operation and maintenance of charging piles for new energy vehicles

The internal controller of the charging pile, electricity meter, battery detection module, etc. exchange data through the CAN bus. The CAN-to-Ethernet device can upload information such as charging pile operating parameters, charging status, and fault codes to the cloud operation and maintenance platform. Operation and maintenance personnel can remotely view the device status and troubleshoot faults without on-site inspection, reducing operation and maintenance costs and ensuring stable operation of the charging pile.

3. Integrated control of intelligent building equipment

In intelligent buildings, devices such as elevator operation controllers, central air conditioning units, and lighting systems often utilize CAN bus communication. CAN-to-Ethernet devices serve as a bridge between the field bus and the building automation system, enabling monitoring of elevator operation status, automatic adjustment of air conditioning temperature, and zoned control of lighting. Additionally, they upload energy consumption data of the devices to the management platform, thereby facilitating energy conservation and consumption reduction in the building.

4. State monitoring of rail transit vehicles

The core components of rail transit vehicles, such as the traction system, braking system, and door control unit, transmit operational data through the CAN bus. The CAN-to-Ethernet device transmits key data such as vehicle speed, brake pressure, and motor temperature to the ground monitoring center in real time, ensuring traffic safety. Additionally, it supports automatic recording of fault data, providing accurate basis for vehicle maintenance and shortening maintenance cycles.

5. Intelligent control of agricultural IoT

In smart agricultural greenhouses, devices such as temperature and humidity sensors, soil moisture monitors, and integrated water and fertilizer dispensers are networked through a CAN bus. CAN-to-Ethernet devices upload collected environmental data and device operation data to the agricultural IoT platform, allowing farmers to remotely monitor the greenhouse environment and automatically control operations such as water and fertilizer irrigation, roller shutter lifting, and more. This enables precise planting and improves the yield and quality of agricultural products.

To meet the demand for CAN-to-Ethernet devices, Shenyang Guangcheng Technology has launched the GCAN-212 device, which features a compact structure and easy installation, with dedicated technical guidance for use. You can reach me on WeChat at 13019325660 for more details, and I welcome you to visit.