9 practical tips in using PLC (Part I)

Today GCAN is going to introduce you some pratical tips in using PLC, let's see what they are.

1. the PLC fault diagnosis itself

In general, PLC is an extremely reliable device with a low failure rate. The tip in using PLC is that probability of hardware damage or software running error of PLC CPU is almost zero; if the PLC input point is not caused by strong power intrusion, it will hardly be damaged; the normally open point of PLC output relay, if it is not short circuit of peripheral load or unreasonable design The load current is out of the rated range and the contact life is also very long.

Therefore, the first tip in using PLC is we should focus on the peripheral electrical components of the PLC, do not always suspect that there is a problem with the PLC hardware or the program, which is very important for quickly repairing faulty equipment and quickly recovering production.

The 2nd tip in using PLC: the input and output (I / O) module selection

The output module is divided into a transistor, a two-way thyristor, and a contact type.

Transistor type has the fastest switching speed (generally 0.2ms), but the load capacity is the smallest, about 0.2~0.3A, 24VDC. It is suitable for fast switching and signal connection equipment. The tip in using PLC that it is generally connected with signals such as frequency conversion and DC device. Pay attention to transistor leakage. The effect of current on the load.

The advantage of the thyristor type is that it has no contact, has AC load characteristics, and has a small load capacity.

The tip in using PLC is that the relay output has AC and DC load characteristics and a large load capacity. In the conventional control, the relay contact type output is generally selected first. The disadvantage is that the switching speed is slow, generally about 10ms, which is not suitable for high frequency switching applications.

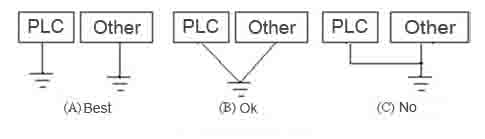

3. the grounding problem

The tip in using PLC is the PLC system generally uses a one-point grounding method. In order to improve the anti-common mode interference capability, the shielded floating ground technology can be used for the analog signal, that is, the shielding layer of the signal cable is grounded at one point, the signal loop is floating, and the insulation resistance with the ground is not less than 50 MΩ.

4. Eliminate the line capacitance to avoid malfunction

There is capacitance between the wires of the cable, and the qualified cable can limit this capacitance to a certain range. Even for qualified cables, when the cable length exceeds a certain length, the capacitance value between the lines will exceed the required value. When this cable is used for PLC input, the line capacitance may cause PLC malfunction. There will be many incomprehensible phenomena.

These phenomena are mainly manifested as: the wiring is correct, but the PLC has no input; the PLC should have some inputs, but there should be some, that is, the PLC inputs interfere with each other. The tip in using PLC to solve this problem, we should:

1. Cables that are twisted together using cable cores;

2. Minimize the length of the cable used;

3. Separate the input from each other using the cable;

4. Use a shielded cable

Do you want to know more points about PLC, please contact us at the right chat interface or send us email: sygckj@gmail.com

1. the PLC fault diagnosis itself

In general, PLC is an extremely reliable device with a low failure rate. The tip in using PLC is that probability of hardware damage or software running error of PLC CPU is almost zero; if the PLC input point is not caused by strong power intrusion, it will hardly be damaged; the normally open point of PLC output relay, if it is not short circuit of peripheral load or unreasonable design The load current is out of the rated range and the contact life is also very long.

Therefore, the first tip in using PLC is we should focus on the peripheral electrical components of the PLC, do not always suspect that there is a problem with the PLC hardware or the program, which is very important for quickly repairing faulty equipment and quickly recovering production.

The 2nd tip in using PLC: the input and output (I / O) module selection

The output module is divided into a transistor, a two-way thyristor, and a contact type.

Transistor type has the fastest switching speed (generally 0.2ms), but the load capacity is the smallest, about 0.2~0.3A, 24VDC. It is suitable for fast switching and signal connection equipment. The tip in using PLC that it is generally connected with signals such as frequency conversion and DC device. Pay attention to transistor leakage. The effect of current on the load.

The advantage of the thyristor type is that it has no contact, has AC load characteristics, and has a small load capacity.

The tip in using PLC is that the relay output has AC and DC load characteristics and a large load capacity. In the conventional control, the relay contact type output is generally selected first. The disadvantage is that the switching speed is slow, generally about 10ms, which is not suitable for high frequency switching applications.

3. the grounding problem

The tip in using PLC is the PLC system generally uses a one-point grounding method. In order to improve the anti-common mode interference capability, the shielded floating ground technology can be used for the analog signal, that is, the shielding layer of the signal cable is grounded at one point, the signal loop is floating, and the insulation resistance with the ground is not less than 50 MΩ.

4. Eliminate the line capacitance to avoid malfunction

There is capacitance between the wires of the cable, and the qualified cable can limit this capacitance to a certain range. Even for qualified cables, when the cable length exceeds a certain length, the capacitance value between the lines will exceed the required value. When this cable is used for PLC input, the line capacitance may cause PLC malfunction. There will be many incomprehensible phenomena.

These phenomena are mainly manifested as: the wiring is correct, but the PLC has no input; the PLC should have some inputs, but there should be some, that is, the PLC inputs interfere with each other. The tip in using PLC to solve this problem, we should:

1. Cables that are twisted together using cable cores;

2. Minimize the length of the cable used;

3. Separate the input from each other using the cable;

4. Use a shielded cable

Do you want to know more points about PLC, please contact us at the right chat interface or send us email: sygckj@gmail.com