What's the PLC communication method?

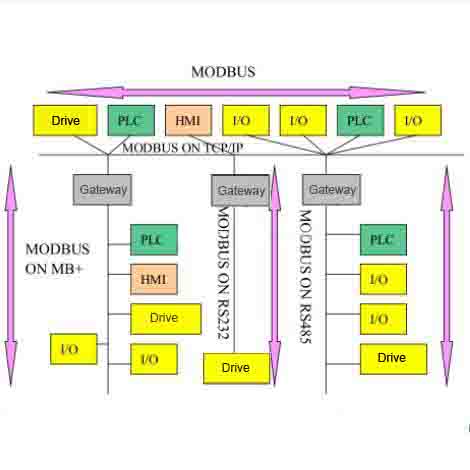

PLC communication mainly adopts serial asynchronous communication, and its commonly used serial communication interface standards include RS-232C, RS-422A and RS-485.

RS-232 and RS-422, when communicating with the host computer, the PLC communication with the computer. If the transmission distance is less than 16 meters, the serial port RS-232 can be used directly. If it is greater than 16 meters, the PS-232/RS-422 converter is used. Convert it to RS-422 and connect it to your computer. RS-232 interface has low data transmission rate, limited transmission distance and poor anti-interference ability. RS-422 adopts full-duplex communication mode Fand adopts differential transmission mode to enhance the anti-common-mode interference capability. Another PLC communication RS-485 is an improvement to RS-422. The difference is that RS-485 uses half-duplex communication.

RS-232, RS-422 and RS-485 PLC communication interface are serial data interface standards originally developed and published by the Electronic Industries Association (EIA):

★★★ PLC communication interface RS-232 was released in 1962 and named EIA-232-E as an industry standard to ensure compatibility between different manufacturers.

★★★ PLC communication interface RS-422 was developed from RS-232, which was proposed to make up for the lack of RS-232. To improve the shortcomings of short RS-232 communication and low speed, RS-422 defines a balanced communication interface that increases the transmission rate to 10 Mb/s and the transmission distance to 4000 ft (at rates below 100 kb/s). It also allows up to 10 receivers to be connected on a balanced bus. RS-422 is a one-way, balanced transmission specification for single-machine transmission and multi-machine reception. It is named TIA/EIA-422-A standard.

★★★ In order to expand the scope of application, EIA developed the PLC communication interface RS-485 standard on the basis of RS-422 in 1983, adding multi-point, two-way communication capability, which allows multiple transmitters to be connected to the same bus, while increasing The driver's drive capability and collision protection feature extend the bus common-mode range and are later named TIA/EIA-485-A. Since the proposed standards proposed by EIA are all prefixed with "RS", in the field of communication industry, it is still customary to prefix the above standards with RS.

GCAN PLC communication not only support serial communication, but also support CAN bus and Ethernet communication.

If you are interested in PLC communication, Click here to view more: http://www1.gcanbox.com/fsd/gyzdh/

RS-232, RS-422 and RS-485 PLC communication interface are serial data interface standards originally developed and published by the Electronic Industries Association (EIA):

★★★ PLC communication interface RS-232 was released in 1962 and named EIA-232-E as an industry standard to ensure compatibility between different manufacturers.

★★★ PLC communication interface RS-422 was developed from RS-232, which was proposed to make up for the lack of RS-232. To improve the shortcomings of short RS-232 communication and low speed, RS-422 defines a balanced communication interface that increases the transmission rate to 10 Mb/s and the transmission distance to 4000 ft (at rates below 100 kb/s). It also allows up to 10 receivers to be connected on a balanced bus. RS-422 is a one-way, balanced transmission specification for single-machine transmission and multi-machine reception. It is named TIA/EIA-422-A standard.

★★★ In order to expand the scope of application, EIA developed the PLC communication interface RS-485 standard on the basis of RS-422 in 1983, adding multi-point, two-way communication capability, which allows multiple transmitters to be connected to the same bus, while increasing The driver's drive capability and collision protection feature extend the bus common-mode range and are later named TIA/EIA-485-A. Since the proposed standards proposed by EIA are all prefixed with "RS", in the field of communication industry, it is still customary to prefix the above standards with RS.

GCAN PLC communication not only support serial communication, but also support CAN bus and Ethernet communication.

If you are interested in PLC communication, Click here to view more: http://www1.gcanbox.com/fsd/gyzdh/