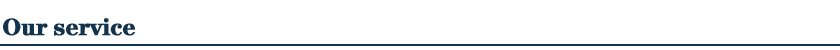

PLC controller series

- Brand:

- GCAN

- Model:

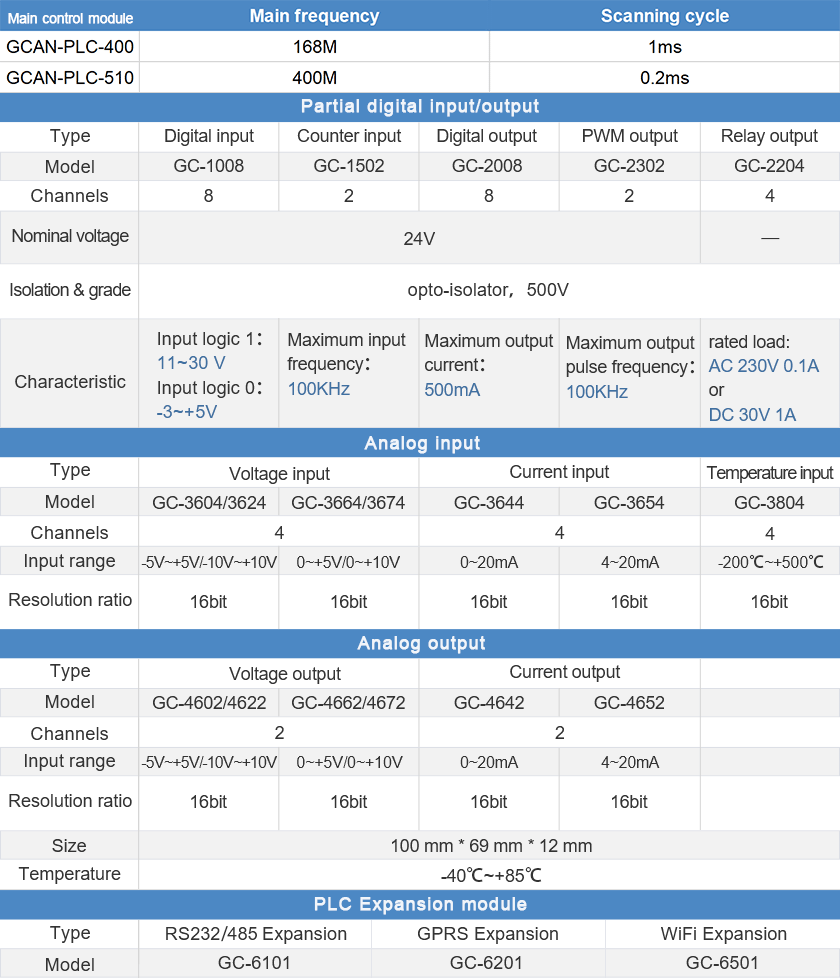

- GCAN-PLC GCAN-PLC-400 GCAN-PLC-510

- Application:

- Provide customizable services; Support WIFI/GPRS expansion module; IO module can be expanded arbitrarily; Support 5 language of IEC61131-3 standard; Support Ethernet;RS232/485;CAN Bus interface;

-

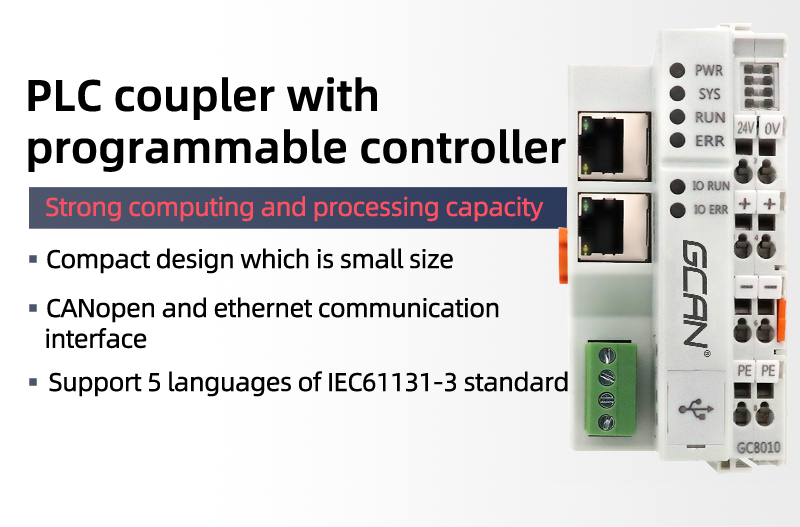

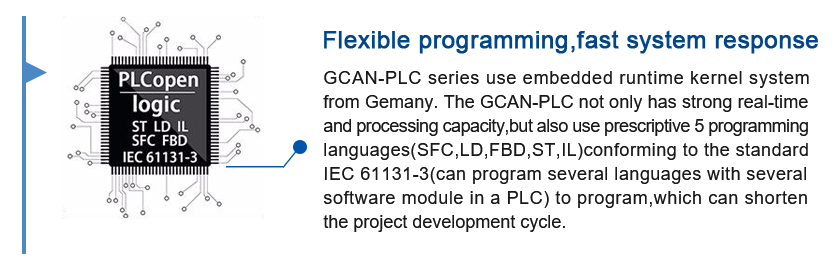

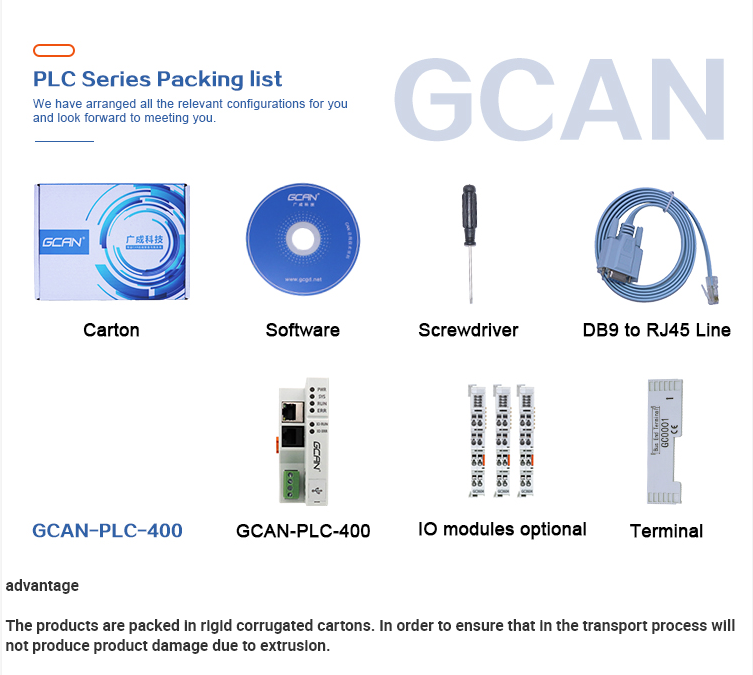

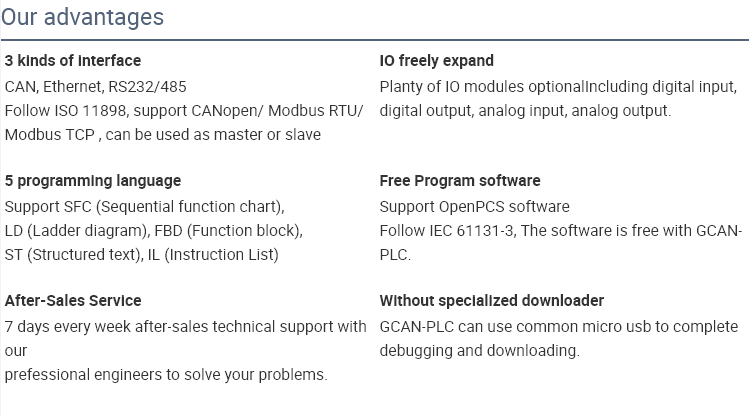

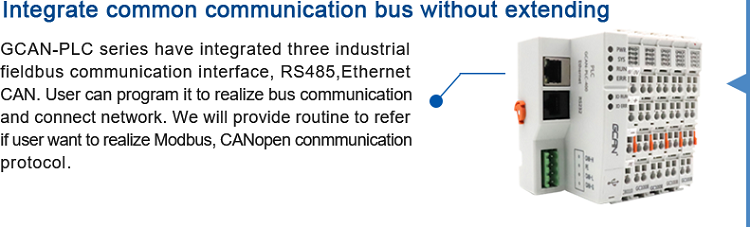

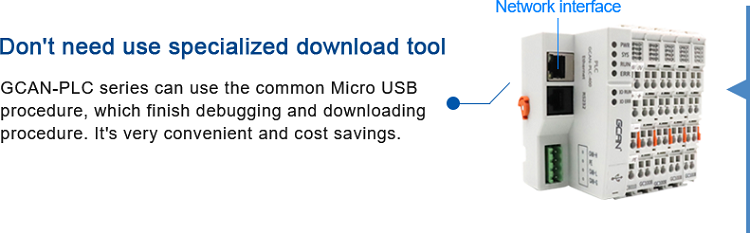

Guangcheng Technology GCAN-PLC is a modular and expandable PLC module. The main control module of the PLC module uses a high-speed CPU, with powerful computing and processing capabilities, and can respond to signals and control commands in real time. The main control module also has a fieldbus communication interface. Users can use these communication buses to access the corresponding network to communicate with other devices, and easily connect it to the communication control network.

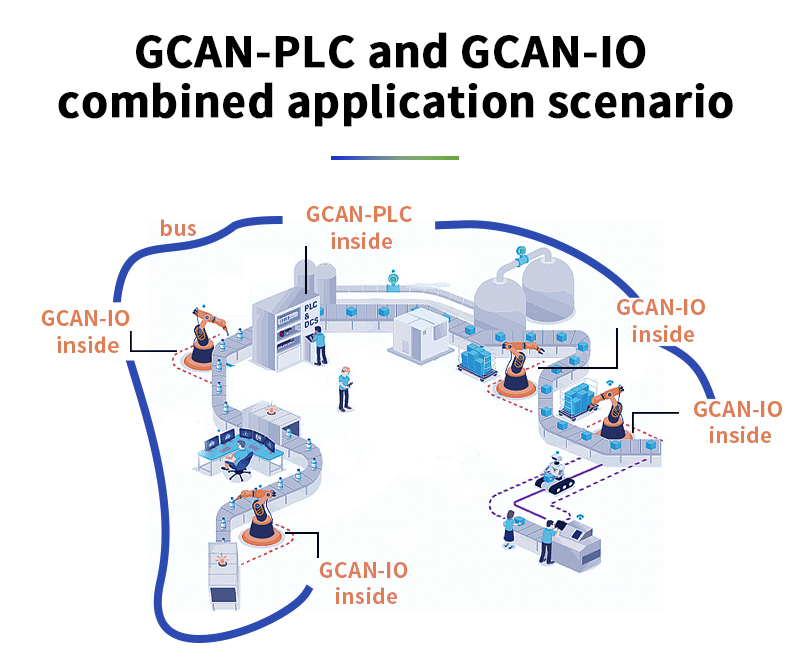

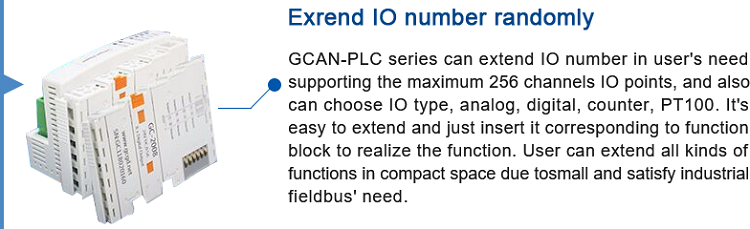

GCAN-PLC consists of a programmable main control module, several I/O modules and a terminal terminal module. Each module uses internal bus to communicate with each other, so users can program and control each I/O module independently. The compact appearance structure and flexible programmable function make this PLC can be used in almost any industrial field control and acquisition system, providing a very effective and economical solution for automation control.

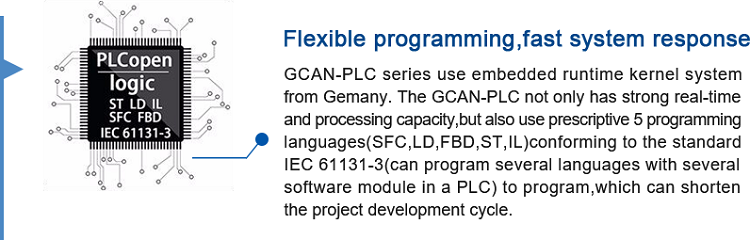

GCAN-PLC can be programmed in five programming languages that comply with the IEC61131-3 standard, including: SFC (Sequential Function Chart), LD (Ladder Diagram), FBD (Function Block), ST (Structured Text), IL (Instruction list). A variety of standard programming languages can be used, which makes the PLC program portable and reusable. IEC61131-3 also allows multiple programming languages to be used in the same PLC, allows program developers to select the appropriate programming language for each specific task, and allows different software modules to use different programming languages in the same control program prepared by.

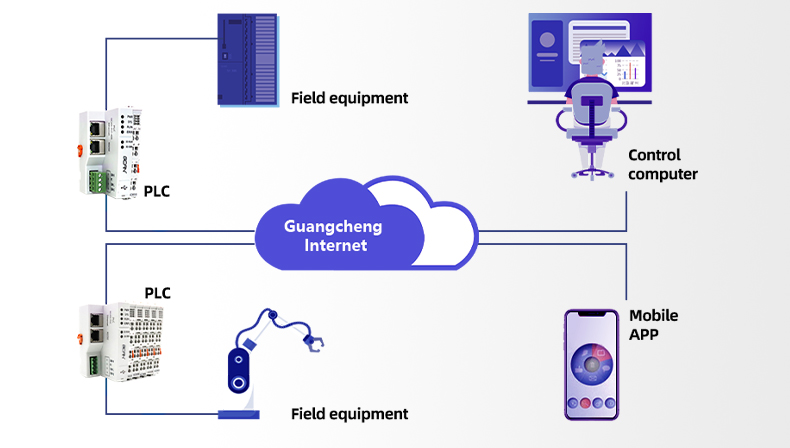

"Guangcheng Internet" industrial Internet platform is a new industrial Internet platform that integrates software services, attachment services and other services. Our company can design a set of digital monitoring and control that meets the user's own needs through the platform. System, users can also use the platform to remotely access field devices to achieve high-end functions such as status monitoring, remote control, fault diagnosis, and unified management of field devices

Facilitating digital upgrading of traditional manufacturingCustomer demand:

Unable to accurately judge the life of consumable parts

When the equipment oil is insufficient, the user can only be reminded on the equipment, which is easily ignored by the workers.

Once the equipment fails, the on-site workers cannot accurately describe the failure

phenomena and problems. Therefore, the manufacturer needs to send professional

engineers to the site for inspection. Once the parts are damaged, they need to be returned to the manufacturer to pick up or mail. The labor cost is very high.GCAN Solution:

Install a dedicated controller, and install various sensors to collect real-time loss parts working conditions and the remaining amount and quality of various oils.

Once the controller judges that the equipment is faulty or has any hidden dangers, it can send the warning information to the designated mobile phone or computer software through the 4G module for the convenience of the management personnel to view.

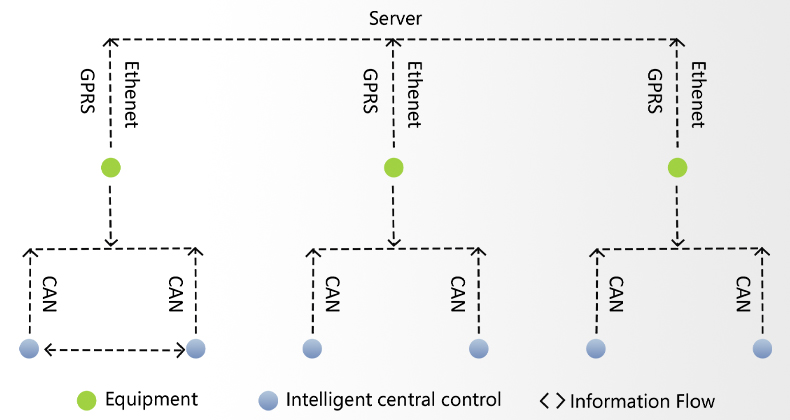

Schematic diagram of data collection:

Help the construction machinery industry improve efficiencyCustomer demand:

Machinery equipment cannot be located after being leased

Once the mechanical equipment fails, it cannot be eliminated and repaired in time

High operating costsGCAN Solution:

Install the main control PLC to monitor the running status of various sensors on the mechanical equipment

The main control PLC is equipped with GPS module, which can realize real-time positioning and dismantling alarm.

Once the mechanical equipment has a fault or early warning, the main control PLC can send the fault or early warning information to the designated mobile phone or computer software through the 4G module, which is convenient for the management personnel to view.Schematic diagram of networking:

After the company upgraded all its mechanical equipment, the company's operating efficiency has been significantly improved, the cost of management personnel has been reduced by 20%, the cost of operating personnel has been reduced by 25%, and the cost of mechanical maintenance has been reduced by 17%

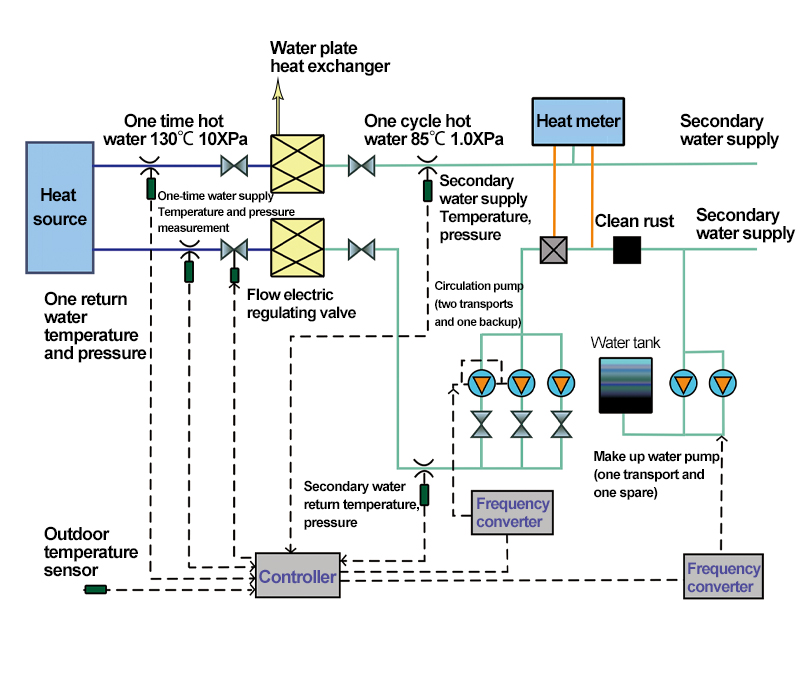

Help HVAC industry to save energy and increase efficiency.Customer demand:

Temperature regulation depends on experience, time-consuming and labor-intensive, with many complaints and big problems .

High labor cost for inspection of heat exchange stations.

Serious waste of energy and uneven heating and cooling.GCAN Solution:

Install electronic flow pressure sensor

Install the inverter and controller .

Install electric flow control valve

Upload to the monitoring center through the PLC control equipment GPRS The heating network center remotely monitors the water supply temperature of each water exchange station. Every day, dispatchers give instructions to the network parameters based on outdoor temperature, house structure, historical data and other related factors that affect heating, and implement precise adjustment of remote heating temperature.Schematic diagram of heat exchange station monitoring:

Common problem

Q:What if you don't know how to program? can you customize it?A:Guangcheng plc supports customized services.

Q:Whether it can be connected to the HMI?

A:Yes.And we have touch screen routines, you can contact us if you need it.Q:What programming software? Is there a charge for software?

A:Guangcheng PLC uses openpcs software. The software is free to use.

Q:How many languages can you program in?

A:Guangcheng plc supports 5 programming languages(LD/IL/FBD/SFC/ST).

Q:Does plc support CANopen protocol?

A:Yes.and we provide related routines.

Q:Can plc do data conversion?

A:Yes.and there are related routines to refer to.

Q:What kind of communication port does plc bring?

A:CAN communication, TCP communication, serial communication.

Q:How does the IO module address correspond?Automatic configuration.

-

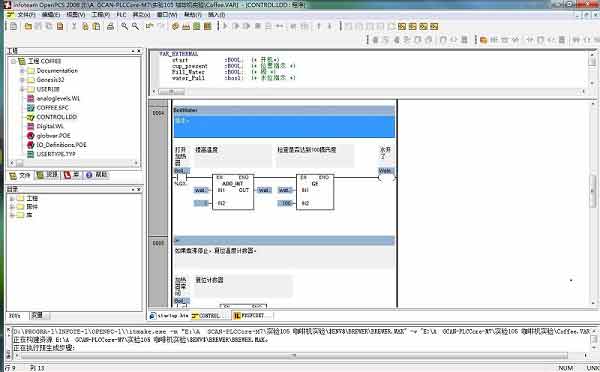

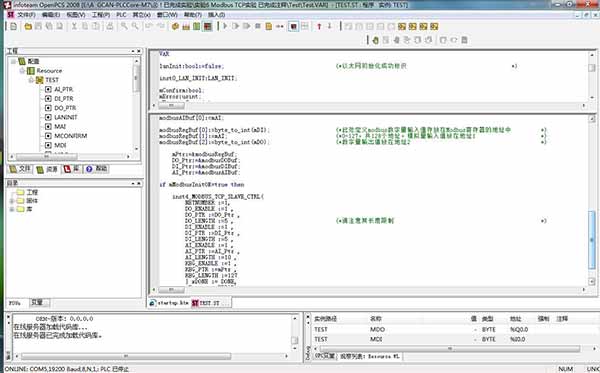

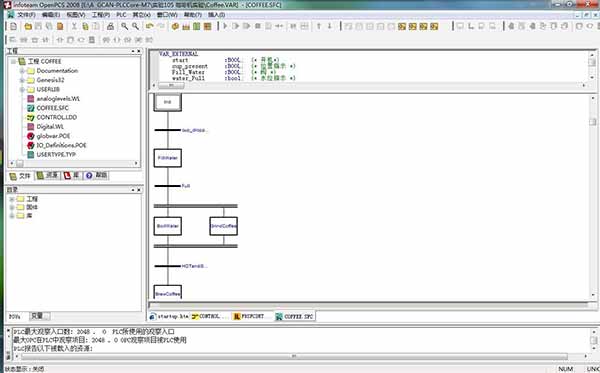

- GCAN-PLC can be programmed with German OpenPCS software. OpenPCS is a powerful PLC

software programming tool. It supports the five PLC programming languages IL, ST, FBD, LD

and SFC specified in the IEC61131-3 standard. Users can select different language editing

subroutines in the same project. Function modules, etc.GCAN will provide users with commonly used function examples such as basic input and output,

basic RS232/RS485/Ethernet/CAN communication, CANopen protocol communication, Modbu

protocol communication, etc., which can be used by users. Quickly develop a PLC application

that suits you, saving development time and reducing development costs.

ST ( Structure Text) ↓ SFC (sequence Function Chart) ↓

SFC (sequence Function Chart) ↓ LD (Ladder Diagram)

LD (Ladder Diagram)