The importance of programmable PLC_GCAN

Programmable PLC is a flexible controller in controller. Not only do we need to be flexible in life, but we do the same in our work. Here we talk about the flexible cases of engineering project construction. In some complicated engineering projects, based on different factors such as capital, environment, weather, technology, etc., some projects may change content in the middle. If the control system that controls the project cannot change its control in a short time. The way, then it will greatly affect the progress of the project, resulting in extremely waste of resources. The old control method such as relay control undoubtedly belongs to this category. Although it is simple in structure, low in price and easy to operate, it also has bulky and bloated, long system production cycle, complicated wiring failure rate, poor reliability and flexibility. The cost of changing control schemes is high, and it is difficult to communicate and network between systems. Relay control is not suitable for projects that require frequent changes to the project.

Engineering projects that require changes at any time

If the relay control is not suitable for the above requirements, then there will be tools suitable for the above requirements. Yes, it is the protagonist we want to talk about today: programmable PLC tools. PLC scientific name programmable logic controller, as the name suggests, it can be programmed, at this point it is destined to be more advanced than relay control. Programmable PLC tools are free to change their control contents through five programming languages: SFC (Sequential Function Chart), LD (Ladder Diagram), FBD (Function Block), ST (Structured Text), and IL (Instruction Table). Compared with the relay control that is completely negated, PLC has high reliability, strong anti-interference ability, fast running speed and perfect functions, which can realize the advantages of complex control functions. Some programmable PLCs using plug-in IO modules are simpler to program and easy to use. The whole system is easy to design, install and debug. The workload of engineers is small, compared with the relay system with the same function. The price is very high.

Programming software of GCAN programmable PLC

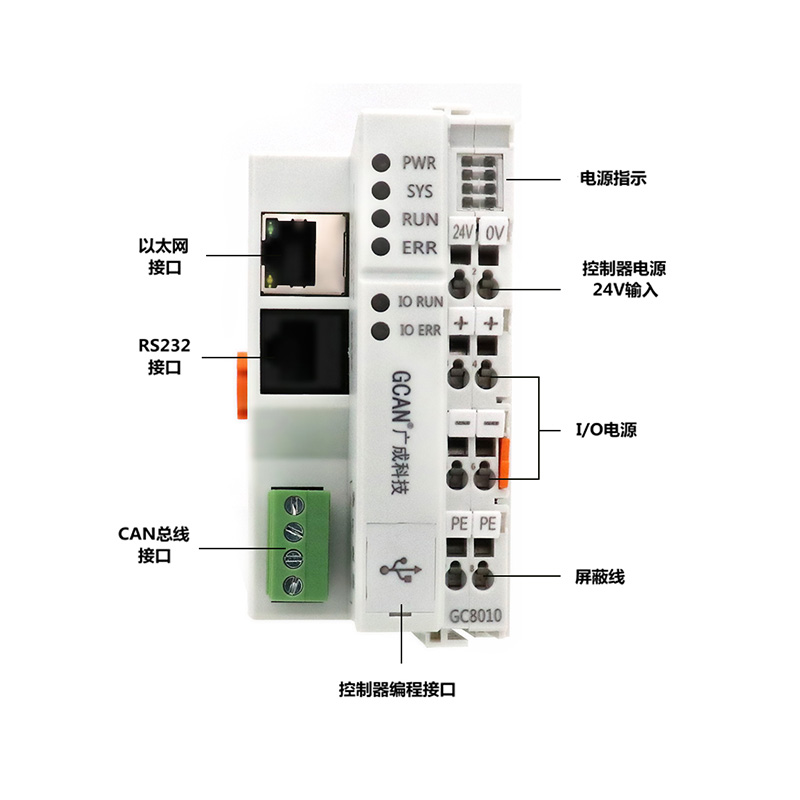

Since programmable PLC tools have so many advantages, is there any product worth recommending? Here I recommend to you the Shenyang Guangcheng Technology GCAN-PLC-400 programmable PLC tool that is very suitable for engineering project control changes. The GCAN-PLC-400 programmable PLC consists of a programmable main control module (GCAN-PLC-400), several GC series IO modules (GC-1008, GC-3804, etc.) and a terminal terminal module. Its main control module can be connected to all GC series IO modules. Users can choose to expand the IO module according to the actual needs of the site. The number of extended IO modules can reach 32. The GCAN-PLC-400 main control module supports automatic configuration. The user does not need to set parameters on the PC. The main control module will be automatically configured according to the front and rear positions of the inserted terminal module.