What's the PLC Scan Cycle? _ GCAN

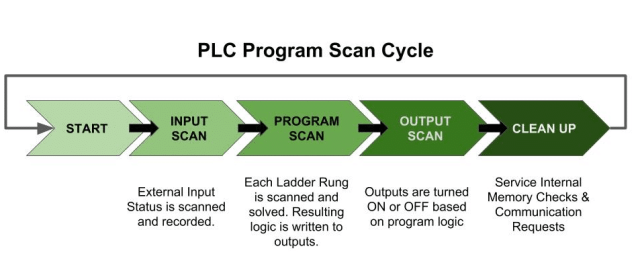

The working process of the programmable controller (a PLC scan cycle) consists of two parts: the fixed process of self-diagnosis and communication response and the execution process of the user program.

Before each execution of the user program, the PLC executes the internal fixed program such as fault self-diagnosis program, reset, monitoring, timing, etc. If the self-diagnosis is normal, continue to scan downward, and then the PLC checks whether there is a communication request with the programmer, computer, etc. If so, it will deal in response.

Before each execution of the user program, the PLC executes the internal fixed program such as fault self-diagnosis program, reset, monitoring, timing, etc. If the self-diagnosis is normal, continue to scan downward, and then the PLC checks whether there is a communication request with the programmer, computer, etc. If so, it will deal in response.

If there is a communication request with a computer or the like, the corresponding processing is performed. When in the STOP state, the PLC scan cycle is included only the first two processes. When the PLC is in the RUN state, the PLC scan cycle is through five working phases: internal processing, communication operation, input scanning, executing user program, and output refresh. The time required to complete each of the above five phases is called a PLC scan cycle.

The PLC scan cycle is an important indicator. The scan cycle of small PLC is generally from ten milliseconds to several tens of milliseconds. The length of the PLC scan cycle depends on the scanning speed and the length of the user program. The scan time in milliseconds is usually allowed for general industrial equipment, and the short delay of the PLC to the input is also allowed.

However, for devices that respond quickly to certain I/Os, they need much shorter PLC scan cycle. The following actions should be taken. You can select a high-speed CPU, increase the scanning speed; select fast response module, high-speed counting module and different interrupt processing to reduce the lag time. The other way to reduce PLC scan cycle is on the engineer who use the PLC. And the user can improve the programming ability, optimize the program as much as possible; while writing the control program of the large device, minimize the program length, select the branch or jump program, etc which can reduce the user program execution time. Our GCAN PLC scan cycle can be as short as several milliseconds.

If you need more details about GCAN products, click here: http://www1.gcanbox.com/

Email/skype: sygckj@gmail.com

Tel/whatsapp: +8613609896275

Facebook: https://www.facebook.com/gcanbox/

Buy it now: Click to buy on Alibaba