PLC: A good tool for industrial production control personnel

In our daily life and work, we hope that we have the most suitable and perfect tools, such as it should be cost-effective, not delay time, easy to use, low failure rate, and easy to repair. The relentless pursuit of such tools is the source of continuous progress of mankind, and the continuous innovation of such tools has promoted the progress of human society. Today we want to talk about the protagonist PLC, which belongs to this class, let us first introduce it specifically:

PLC, short for Programmer Logic Controller, is a kind of control equipment, and it is also a kind of digital computing operation electronic device specially designed for industrial production. It uses a class of programmable memory for its internal memory program, performing user-oriented instructions such as logic operations, sequence control, timing, counting and arithmetic operations, and controlling various types of machinery and the production process through digital or analog input/output. As the core part of industrial control, it is widely used in various industries such as steel, petroleum, chemical, electric power, building materials, machinery manufacturing, automobile, textile, transportation, environmental protection and culture and entertainment. So the question is, why is the PLC so popular? Below, we will compare it with the traditional relay control equipment from many aspects, and feel the outstanding features of the PLC:

1. In terms of equipment volume, PLC equipment is much smaller than relay control equipment, which is determined by their own characteristics. The relay equipment is bulky and bloated due to the complicated wiring. In some projects where the production space control is relatively high, it is not suitable actually. The PLC has a small shape, convenient wiring and strong adaptability, which is one of the reasons for its popularity.

2. In the system construction, the production cycle of the relay equipment is very long. After all, its circuit is too diverse, and it is for this reason that the flexibility of its modification is very poor, and the cost of changing the control scheme is high. PLC programmable controller is very convenient in design, installation, and debugging of the system with small workload. It is a very important point in the industrial production field.

3. PLC programmable logic controller, as its name, is an intelligent industrial control device capable of programming operation. The engineer can edit the corresponding program to modify the corresponding process and optimize the specific production without changing the hardware. The relay control device system is difficult to communicate with each other, and is only suitable for industrial applications where the working mode is fixed and the control logic is simple. Therefore, the industrial control personnel urgently need a controller with a small volume, short system production cycle, simple wiring, low failure rate, better reliability and flexibility, low cost of control scheme, and direct communication between systems. PLC programmable logic controllers basically meet all their requirements.

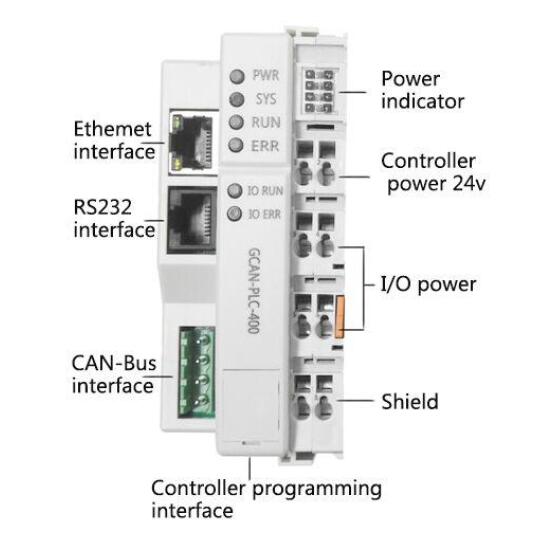

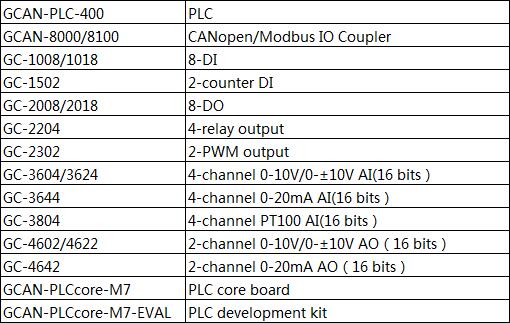

GCAN focusing on the needs of industrial development, In order to meet the development needs of industrial control personnel, introduces the PLC programmable controller device GCAN-PLC series, which is a modular and arbitrarily expandable PLC module. The module consists of a programmable main control module (GCAN-PLC-400), several I/O modules and a terminal module. The main control module uses a high-speed CPU with powerful computing and processing capabilities. It also has three fieldbus communication interfaces: Ethernet, RS232/485, and CAN. Users can use these communication buses to access the corresponding network to communicate with other devices. Here's a table for IO modules below which basically meet all types of PLC production control needs, is the best helper for industrial control personnel.

PLC, short for Programmer Logic Controller, is a kind of control equipment, and it is also a kind of digital computing operation electronic device specially designed for industrial production. It uses a class of programmable memory for its internal memory program, performing user-oriented instructions such as logic operations, sequence control, timing, counting and arithmetic operations, and controlling various types of machinery and the production process through digital or analog input/output. As the core part of industrial control, it is widely used in various industries such as steel, petroleum, chemical, electric power, building materials, machinery manufacturing, automobile, textile, transportation, environmental protection and culture and entertainment. So the question is, why is the PLC so popular? Below, we will compare it with the traditional relay control equipment from many aspects, and feel the outstanding features of the PLC:

1. In terms of equipment volume, PLC equipment is much smaller than relay control equipment, which is determined by their own characteristics. The relay equipment is bulky and bloated due to the complicated wiring. In some projects where the production space control is relatively high, it is not suitable actually. The PLC has a small shape, convenient wiring and strong adaptability, which is one of the reasons for its popularity.

2. In the system construction, the production cycle of the relay equipment is very long. After all, its circuit is too diverse, and it is for this reason that the flexibility of its modification is very poor, and the cost of changing the control scheme is high. PLC programmable controller is very convenient in design, installation, and debugging of the system with small workload. It is a very important point in the industrial production field.

3. PLC programmable logic controller, as its name, is an intelligent industrial control device capable of programming operation. The engineer can edit the corresponding program to modify the corresponding process and optimize the specific production without changing the hardware. The relay control device system is difficult to communicate with each other, and is only suitable for industrial applications where the working mode is fixed and the control logic is simple. Therefore, the industrial control personnel urgently need a controller with a small volume, short system production cycle, simple wiring, low failure rate, better reliability and flexibility, low cost of control scheme, and direct communication between systems. PLC programmable logic controllers basically meet all their requirements.

GCAN focusing on the needs of industrial development, In order to meet the development needs of industrial control personnel, introduces the PLC programmable controller device GCAN-PLC series, which is a modular and arbitrarily expandable PLC module. The module consists of a programmable main control module (GCAN-PLC-400), several I/O modules and a terminal module. The main control module uses a high-speed CPU with powerful computing and processing capabilities. It also has three fieldbus communication interfaces: Ethernet, RS232/485, and CAN. Users can use these communication buses to access the corresponding network to communicate with other devices. Here's a table for IO modules below which basically meet all types of PLC production control needs, is the best helper for industrial control personnel.

Welcome to contact us, if you want to know more about GCAN and GCAN products.

Tel: +86 13609896275.

Email: sygckj@gmail.com