How to troubleshoot interruption of GCAN PLC with CAN

GCAN-PLC series is a modular, arbitrarily expandable PLC with CAN controller. The controller consists of a CPU and several expansion IO modules. CPU defaults to three different types of bus interfaces: Ethernet, CAN, and RS23/485. The IO module has multiple types of digital and analog input/output modules. Users can select different types of modules according to their needs. Match it.

GCAN-PLC is a programmable logic controller (PLC with CAN bus). Exquisite shape, cost-effectiveand freely I/O expansion. PLC with CAN can be programmed using OpenPCS software, which supports five standard programming languages as specified in the IEC-61131-3, this makes the program highly portable and reusable, and the software also has a variety of Debugging functions (such as breakpoints, single step, monitoring, etc.) make the debugging program more convenient.

Click here to learn more about GCAN PLC with CAN or CANopen

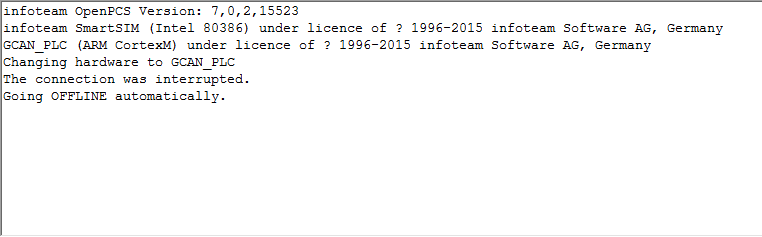

Engineer Zhang from a company in Shanghai encountered the following error when using our PLC to connect.

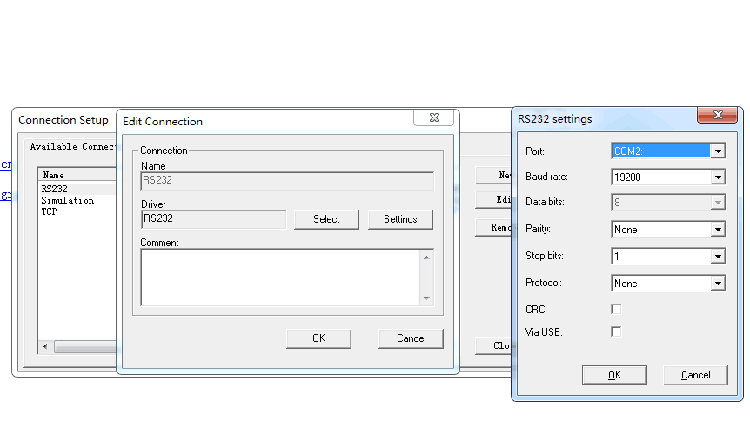

The reason for this problem is generally that the communication parameters set by the software are incorrect. When asked what the communication parameters set by Engineer Zhang OpenPCS software(PLC with CAN) are, he gave me the following screenshot:

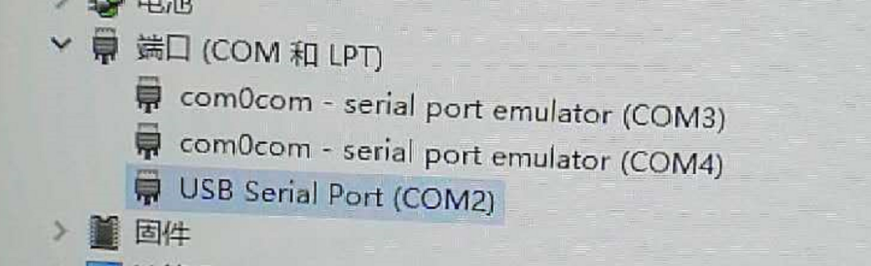

From the screenshot we can see that the serial port number is COM4, the communication baud rate is 9600, the data bit is 8, no parity, the stop bit is 1, the protocol is none. After that, I asked Zhang Gong to find the serial port number of GCAN-PLC in the computer equipment manager. After he found it, he gave me the following screenshot:

From the above screenshot, we can see that the actual serial port number after the PLC with CAN port is connected to the computer is actually COM2, not the COM4 set by the software, so it will cause the communication error of the connection time of the connection, and set the serial port number of the OpenPCS software. After COM2, you can communicate and download the program normally.

Our Engineer reminds everyone here: no matter what kind of communication method is used, it is necessary to set the parameters accurately, then it can communicate normally. Therefore, when debugging PLC with CAN-bus and other devices, the serial port connection is not found, most of them are because of communication parameter settings. Errors, such as: COM port port number setting error, COM port is occupied, COM port hangs, etc. In the error check, you can check the computer device manager to determine the port number of the COM port, and then see if other software that uses the serial port is running. If necessary, restart the computer and then open the software that must be used to avoid the COM port hangs or Occupied.

Don't waiting, contact us and get one.

Email/Skype: seven.gcan@gmail.com

Tel: +86 17742765166