DIY your own PLC with GCAN PLC core module

As the core component of industrial automation control, PLC has developed rapidly in the 1980s and 1990s. With the continuous improvement of the automation level of the factory and the continuous expansion of the PLC controller market capacity base, PLC has grown rapidly in developing countries such as China in recent years. Siemens and Mitsubishi still occupy the market share of most PLCs, and the PLC products on the market are all fixed due to their functions and IO points. Therefore, customers have no way to change according to actual needs, which leads to some customers. Although helpless, they still have to pay for features they don't need, so customers urgently need a dedicated controller (PLC) that meets their needs.

The first PLC

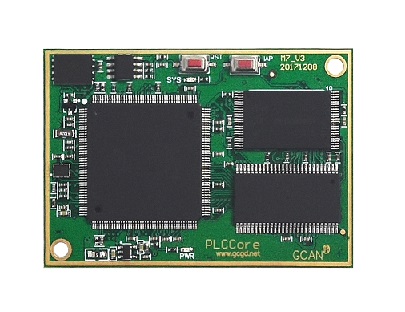

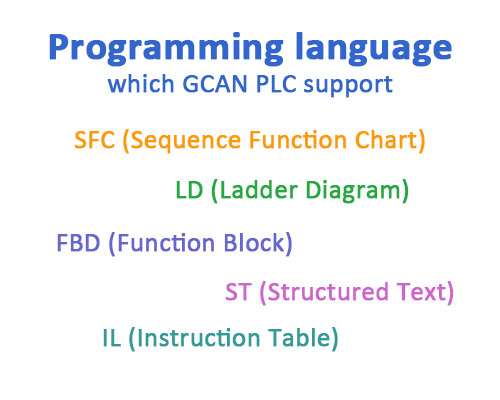

In order to meet the above needs of customers, GCAN Tech has developed a PLC core module, which has pre-installed the IEC 61131-3 runtime kernel. It is a plug-and-play core module with a rich input/output interface such as digital/analog, and also supports various industrial fieldbus communications such as CAN, Ethernet, and serial. The core module supports OEM or customization. The users only need to embed the core module into their own hardware system to achieve bus communication capability or IO control capability. The software supports five programming languages, including: SFC (Sequence Function Chart), LD (Ladder Diagram), FBD (Function Block), ST (Structured Text), and IL (Instruction Table). The flexible development environment and rich functions enable users to quickly build their own PLC control system using this core module, reducing development costs.

Flexible use of PLC core modules can achieve a lot of special needs. Last week, Engineer Yang from an automation company in Suzhou contacted us with such a requirement: He needs to use one device to monitor data in two CAN bus systems simultaneously, control 10 relays in the field, and the device itself preferably needs to support diagnosis through the serial port. After understanding his requirement, we judged that the existing standard products on the market cannot meet these functions at the same time. Therefore, we asked wthether he has PLC programming experience. He is familiar with PLC programming, then GCAN PLC core module is recommended. He buys the PLC core module and then goes back to programming himself to implement whatever he wants.

Programming language which GCAN PLC core module support

Finally, remind the users, if you want to develop a dedicated controller, and you should be familiar with the PLC programming and hardware design or have the ability to have resources, then you can buy the PLC core module to develop your own functions. Once you develop it yourself, your customers can't buy off-the-shelf finished products from other manufacturers, which effectively protects your development results, and most importantly, users who use PLC core modules do not need to write the underlying kernel files, only need to develop a application in the PLC system which will save users a lot of time and cost, and the products developed can be quickly put into the market.

Welcome to contact us, if you want to know more about GCAN PLC core module and GCAN products.

Email/skype:sygckj@gmail.com

Tel/whatsapp: +8613609896275

Facebook: https://www.facebook.com/gcanbox/

Buy it now: Click it on Alibaba

Welcome to contact us, if you want to know more about GCAN PLC core module and GCAN products.

Email/skype:sygckj@gmail.com

Tel/whatsapp: +8613609896275

Facebook: https://www.facebook.com/gcanbox/

Buy it now: Click it on Alibaba