Knowledge of industrial PLC programmable logic controller

When programmable logic controllers were born in the late 1960s, they revolutionized the manufacturing industry and gave machinery a sense of intelligence. Since then, the programmable logic controller market has exploded with multiple manufacturers designing platforms with increasing I/O capacity, memory, speed, scalability, and control capabilities.

Obviously, all PLC manufacturers claim to have the best platform on the market, and selecting the best platform for a given project can be demanding. Often, cost is not the major factor when choosing a programmable logic controller system, and there are other concerns such as future expansion capabilities, ease of maintenance, and availability of replacement parts.

Gcan-plc series of Guangcheng technology is a kind of modularized and expandable PLC module. This module is composed of a programmable main control module (gcan-plc-400), several I / O modules and a terminal module. The main control module uses high-speed CPU and has strong computing and processing capabilities. The main control module also has a variety of field bus communication interfaces, users can use these communication buses to access the corresponding network and communicate with other devices.

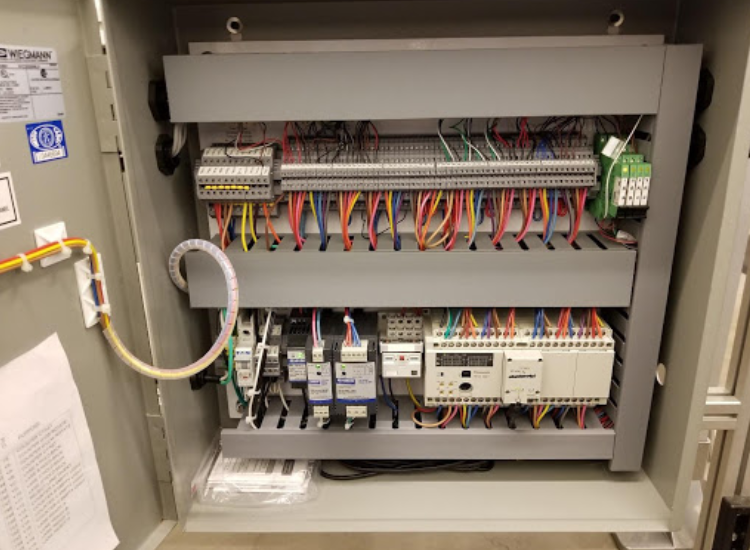

Industrial automation uses set-up technology and automatic control equipment to operate the manufacturing process with minimal manual intervention. Almost every industrial operation is automated in some form by a programmable logic controller (PLC). These are usually buried somewhere in the control panel and perform background operations where workers or maintenance personnel usually see them, but they are a key part of the operation.

The biggest benefit of automation is increased productivity through better control of production. Mass production can be facilitated by significantly reducing unit assembly time and improving production quality.

PLC programming requires the creation of internal logic for the programmable logic controller. The programmable logic controller provides automatic control functions based on sensor inputs. It consists of various communication modules that perform certain automatic operations in the process. They can be designed for multiple arrangements of digital and analog I / O, extended temperature range, resistance to electrical noise, and resistance to vibration and shock.

Gcan-plc series modules have three kinds of communication buses, Ethernet, RS232 / 485 and can, so the module can communicate with most of the intelligent devices in the industrial field (such as PC, touch screen, other PLCs, etc.). Because of its good networking and communication ability, users can completely replace the original multiple communication conversion modules with a gcan-plc, realize centralized collection and control, and enhance the reliability of the whole system.

For the early automation control system, PLC is only used to collect and control the field IO, so it does not need to have the bus communication ability. However, with the improvement of production technology and the improvement of accuracy requirements, people have more and more strong demand for high integration and high intelligent control system. Customers need PLC with bus communication ability. Gcan-plc series modules of Guangcheng technology have three kinds of field bus communication interfaces. For some users who need intelligent centralized control, using gcan-plc series will be very easy to carry out system integration and design, which will also effectively save users' time and development cost, and make the work twice the result with half the effort.