It turns out you are such a PLC. Guangcheng Technology

Up to now, we can't do without the company of computers in our work. Even today's mobile phones can be regarded as microcomputers. Although the computer looks very tall, but its working principle is relatively simple, right, logical operation, either right or wrong. The most basic logical judgment is that kind of binary calculation. Only 1 and 0,1 are yes, 0 is no, after countless choices of yes or no, a specific instruction is sent out and the corresponding work is completed. The above is a kind of understanding of computer logical calculation. Yes, my personal understanding. PLC is also a kind of computer in principle, but it is not exactly the same as computer. Today, let's briefly introduce this kind of equipment and see what its features are.

In terms of function, PLC is used to replace relay to realize logic control. Compared with traditional relay control mode, PLC has the following advantages:

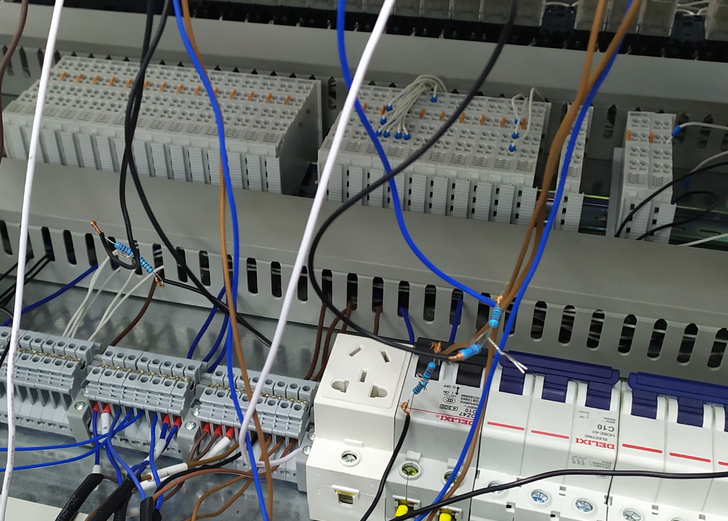

1. In terms of wiring quantity, the wiring quantity of PLC is obviously less than that of relay equipment, at least on the surface display. Less number of line connections means that both installation and disassembly are more time-saving. At the same time, with less lines, the probability of mutual influence between them is also smaller, and the possibility of damage is also smaller. In this way, the maintenance is more worry free, at least it does not need to check one by one. This is also a very important use of PLC to replace the relay The decisive factor is another one.

2. We also mentioned above that PLC is a computer that can carry out logical operation. It can be programmed. This is very useful. Why? Because, this involves controlling the change of the project. We know that no one of all things is immutable. They will change one way or another in the process of development. At this time, we need to make corresponding adjustments to adapt to changes. Because of various factors such as natural human factors, the probability of change of control project content is very high. If the relay control equipment is used, it's a coincidence. Please start again. What about PLC? This is very convenient, through the function block and other programming software, PLC can complete the change of the project control content in a short time, with great flexibility. In comparison, this will save the project team a lot of human and time costs. If it's you, which one should you choose?

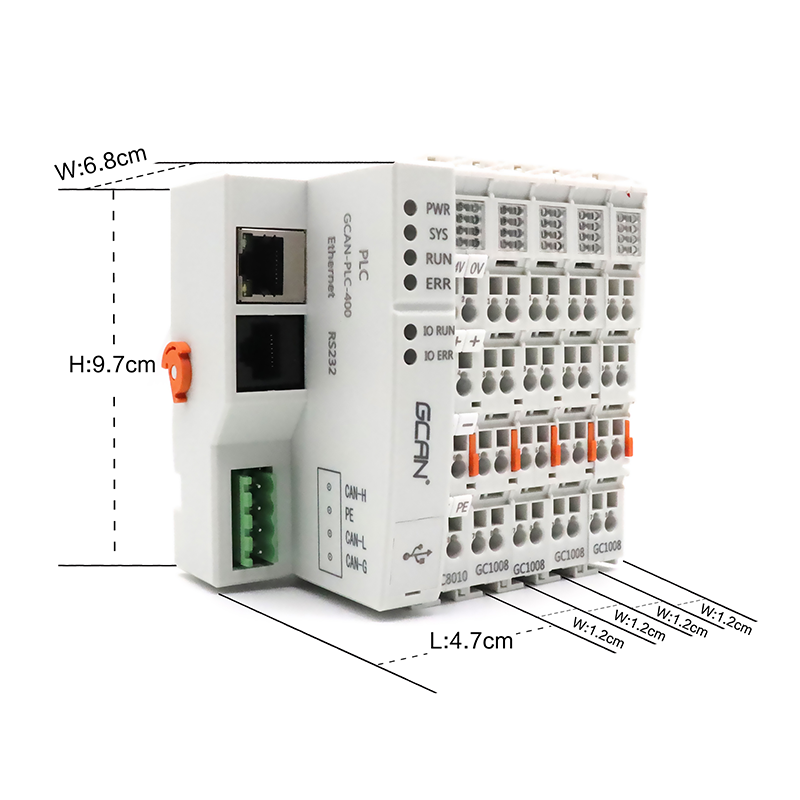

Because of these advantages, PLC is widely used in steel, petroleum, chemical industry, electric power, building materials, machinery manufacturing, automobile, light textile, transportation, environmental protection, cultural entertainment and other industries. It is one of the core components of the future industrial Internet construction, with a broad development prospect. In the long run, its future development trend is portability and miniaturization. Now it looks like this: a main control module which integrates at least three kinds of bus communication interfaces. The bus type should support serial port, network port and can. In this way, it has better data transmission adaptability. At the same time, the part of realizing the function is changed to the function piece that can be installed in time. Different function pieces contain special functions, which can be used alone or in combination with each other. What needs to be installed can avoid the embarrassment of only a bunch of functions that can not be used but cost a lot of money. Finally, in order to ensure the circuit connection of the whole system, the miniaturized PLC should also have a corresponding remote terminal component. The circuit is not working. What else can we talk about?

In order to meet the needs of the majority of PLC users, Shenyang Guangcheng Technology Co., Ltd. has also launched the corresponding miniaturized PLC, namely gcan-plc series. Gcan-plc series PLC programmable controller of Shenyang Guangcheng science and Technology Co., Ltd. is a bus module controller integrated with PLC function. It can be used to connect can bus system, MODBUS system and distributed bus terminal module, and these terminal modules can be expanded by modularization.

Gcan-plc series PLC programmable controller consists of a programmable main control module (gcan-plc-400), several GC series IO modules (gc-1008, gc-3804, etc.) and a terminal module. Gcan-plc series PLC programmable controller main control module can connect all GC series IO modules, users can choose to expand IO modules according to the actual needs of the site, and the number of expansion IO modules can reach 32. Gcan-plc-400 main control module supports automatic configuration. Users do not need to set parameters on the PC. The main control module will automatically configure according to the front and rear positions of the inserted terminal module.

Gcan-plc series PLC programmable controller can use openpcs software to program it. The software supports five kinds of standard programming languages according to iec-61131-3 standard, which makes the program portability and reusability very strong. Moreover, the software also has many debugging functions (such as breaking point, single step, monitoring, etc.), making the debugging program more convenient