CAN bus data recorder logging data offline for detection

As one of the most promising industrial buses recognized internationally, CAN bus has been widely used in various industrial and automotive fields due to its excellent characteristics, such as: commissioning and adjustment of industrial equipment, equipment failure detection and position, interconnection of various industrial fieldbuses, construction of IOT, installation control of smart homes, development and upgrade of automotive electronic products, use of car ECU downloaders, formation of car networking, high-speed rail, motor trains, and car data offline Record and so on. It already has its own international standard (ISO11898), with ultra-fast data transmission distance (above 10KM), ultra-fast data transmission speed (baud rate 1Mbps), a large number of connectable node devices (theoretical one CAN bus can be connected to 110 nodes at the same time). With unparalleled immunity, the CAN bus has become one of the most widely used fieldbuses. In North America and Western Europe, the CAN bus protocol has become the standard bus for automotive computer control systems and embedded industrial control LANs, and has the J1939 protocol designed for large trucks and heavy machinery vehicles with CAN as the underlying protocol.

It is precisely because of the many advantages of the CAN bus that the CAN bus business is booming. But like all consumer products, the CAN bus will have problems sometime, so it requires engineers to go to the problem site for maintenance. But at the same time, another problem has arisen. Sometimes the problem period of the CAN bus is very long. It is often shows no specific problem during the time period of CAN bus maintenance personnel detection. After judged no problem, the problem may occur again in the near future. At this time, CAN bus maintenance personnel need to use the CAN bus analyzer for real-time detection. On the one hand, it is extremely labor-intensive. On the other hand, because of the uncertainty of the time of the problem, the problem often occurs but the staff does not notice and jump. Over. So, is there any way to solve the above difficulties? That's right, a dedicated CAN bus data recorder tool came into being.

It is precisely because of the many advantages of the CAN bus that the CAN bus business is booming. But like all consumer products, the CAN bus will have problems sometime, so it requires engineers to go to the problem site for maintenance. But at the same time, another problem has arisen. Sometimes the problem period of the CAN bus is very long. It is often shows no specific problem during the time period of CAN bus maintenance personnel detection. After judged no problem, the problem may occur again in the near future. At this time, CAN bus maintenance personnel need to use the CAN bus analyzer for real-time detection. On the one hand, it is extremely labor-intensive. On the other hand, because of the uncertainty of the time of the problem, the problem often occurs but the staff does not notice and jump. Over. So, is there any way to solve the above difficulties? That's right, a dedicated CAN bus data recorder tool came into being.

In order to meet the actual maintenance and upgrade requirements of the majority of CAN bus engineers and related CAN bus maintenance personnel, GCAN has also developed the CAN bus data recorder tool GCAN-401 with independent intellectual property rights, which is specially used for storing CAN bus data module. Integrated 1 standard CAN bus interface, GCAN-401 CAN bus data recorder tool can be connected to the CAN bus to realize real-time storage of CAN bus data.

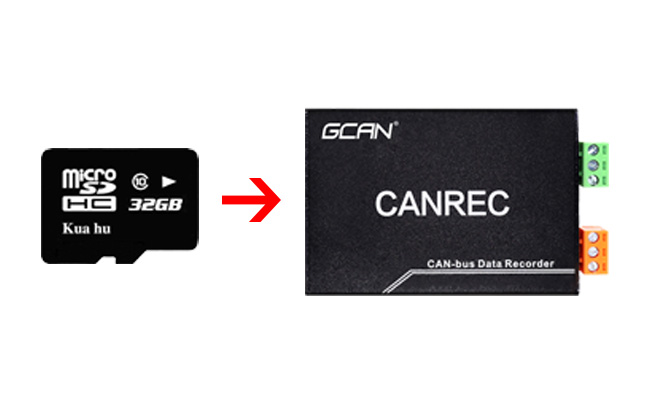

The GCAN-401 CAN bus data recorder tool uses a TF memory card for storing data. It stores the data on the bus in real time to the TF memory card for off-line off storage. After the storage is finished, the CAN bus engineer or maintenance personnel only need to bring the TF card back, and restore the stored data to the real bus data through the dedicated software. It does not need to be detecting in the problem site at any time, which not only liberates the manpower, but also improves the work. s efficiency.

The GCAN-401 CAN bus data recorder tool is suitable for systems that require CAN bus history data acquisition, packet analysis before and after failure. It can be widely used in automobiles, rail vehicles, industrial control and other systems with large data volume and difficult to troubleshoot, such as:

1. Real-time recording of high-speed rail control cabinet communication.

2. Real-time monitoring and recording of communication of subway electrical cabinets.

3. Record and playback of car data.

4. Unmanned monitoring of CAN bus data recording work.

5, CAN bus fault record analysis work.

The GCAN-401 CAN bus data recorder tool uses a TF memory card for storing data. It stores the data on the bus in real time to the TF memory card for off-line off storage. After the storage is finished, the CAN bus engineer or maintenance personnel only need to bring the TF card back, and restore the stored data to the real bus data through the dedicated software. It does not need to be detecting in the problem site at any time, which not only liberates the manpower, but also improves the work. s efficiency.

The GCAN-401 CAN bus data recorder tool is suitable for systems that require CAN bus history data acquisition, packet analysis before and after failure. It can be widely used in automobiles, rail vehicles, industrial control and other systems with large data volume and difficult to troubleshoot, such as:

1. Real-time recording of high-speed rail control cabinet communication.

2. Real-time monitoring and recording of communication of subway electrical cabinets.

3. Record and playback of car data.

4. Unmanned monitoring of CAN bus data recording work.

5, CAN bus fault record analysis work.

Welcome to contact us, if you want to know more about GCAN and GCAN products.

Tel: +86 13609896275.

Email: sygckj@gmail.com