The importance of plc comes with canopen

Now the smartphone we use basically has few people installing TF memory cards on it. On the one hand, there are hundreds of GB of memory in smartphones today. If not too many movies are stored, it is actually enough. On the other hand, the installation of external memory cards on smartphones is generally very unreliable, and there are often situations where recognition cannot be read or data is lost.

PLC is a programmable logic controller. Generally, large-scale factory assembly lines use this thing for control. Compared with the traditional relay controller, it has less wiring, small size, strong anti-interference ability, convenient installation and disassembly, and most importantly, it is a controller that can be programmed. At that time, it only needs a simple operation through programming software to achieve its purpose. If it is replaced by a relay controller, it can only be pushed back. It can be seen that PLC and other devices are very promising in the field of industrial control and market prospects, so many manufacturers at home and abroad have carried out research on it. However, most PLCs only have two communication interfaces, serial interface and Ethernet interface, and the working efficiency of the device will be greatly restricted when it is used. Therefore, integrating the CAN bus interface on the PLC has become a matter of course.

Some friends may have doubts. Didn’t you say that the PLC now has a serial interface and an Ethernet interface, then can I use the corresponding data conversion gateway to transfer it? For example, use the Ethernet to CAN device to convert the Ethernet data on the PLC to CAN data and then connect to the CAN bus. The same applies to the serial bus. Here I can be responsible and tell you that this solution is not at all faulty, but the addition of a device may mean that what could be done in one step now requires several steps to achieve, and the difficulty may be As the geometric multiple increases, the error rate is also higher. Therefore, why don't we omit the middle step and directly choose the PLC with integrated CAN bus interface?

PLC is a programmable logic controller. Generally, large-scale factory assembly lines use this thing for control. Compared with the traditional relay controller, it has less wiring, small size, strong anti-interference ability, convenient installation and disassembly, and most importantly, it is a controller that can be programmed. At that time, it only needs a simple operation through programming software to achieve its purpose. If it is replaced by a relay controller, it can only be pushed back. It can be seen that PLC and other devices are very promising in the field of industrial control and market prospects, so many manufacturers at home and abroad have carried out research on it. However, most PLCs only have two communication interfaces, serial interface and Ethernet interface, and the working efficiency of the device will be greatly restricted when it is used. Therefore, integrating the CAN bus interface on the PLC has become a matter of course.

Some friends may have doubts. Didn’t you say that the PLC now has a serial interface and an Ethernet interface, then can I use the corresponding data conversion gateway to transfer it? For example, use the Ethernet to CAN device to convert the Ethernet data on the PLC to CAN data and then connect to the CAN bus. The same applies to the serial bus. Here I can be responsible and tell you that this solution is not at all faulty, but the addition of a device may mean that what could be done in one step now requires several steps to achieve, and the difficulty may be As the geometric multiple increases, the error rate is also higher. Therefore, why don't we omit the middle step and directly choose the PLC with integrated CAN bus interface?

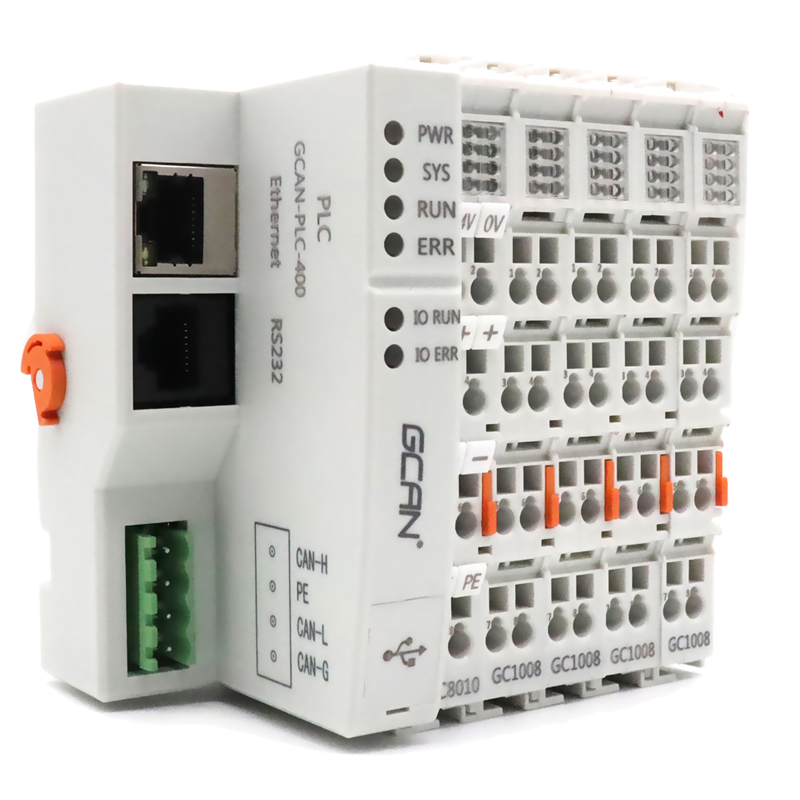

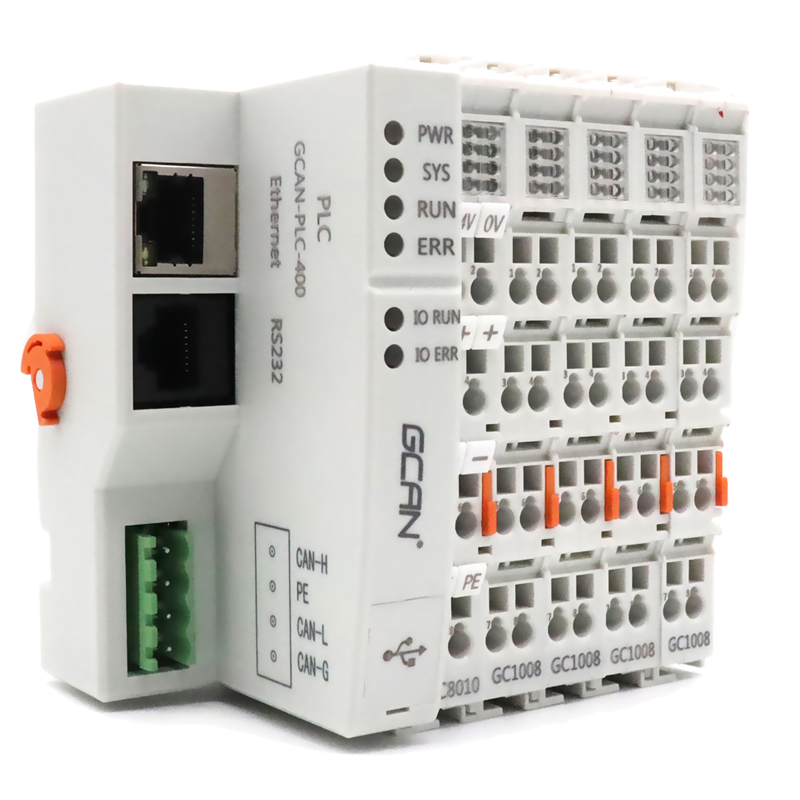

Shenyang Guangcheng Technology GCAN-PLC is a bus module controller with integrated PLC function. It has the characteristics of compact shape and high cost performance, and can be used to connect CAN bus system, Modbus system and distributed bus terminal modules, and these terminal modules can be expanded in a modular manner.

Shenyang Guangcheng Technology GCAN-PLC is composed of a programmable main control module (GCAN-PLC-400), several GC series IO modules (GC-1008, GC-3804, etc.) and a terminal terminal module. The GCAN-PLC-400 main control module can be connected to all GC series IO modules. The user can choose to expand the IO module according to the actual needs of the site. The number of expansion IO modules can reach 32. The GCAN-PLC-400 main control module supports automatic configuration, users do not need to set parameters on the PC, the main control module will be automatically configured according to the front and rear positions of the inserted terminal module.