The urgency of compact plc development from the current inte

The excitement of the eleventh military parade has not passed, and we were swiped by a less friendly news. That is the NBA Rockets general manager Morey’s Hong Kong independence speech has greatly affected the cooperation between the NBA and China. Now we have completely banned the NBA preseason live broadcast. If the incident is not properly resolved, the US personnel refused. If you don't apologize, I believe that the NBA can basically withdraw from China. This is not only the burst of our patriotic sentiment, but also to some extent reveals the double-standard concept of the Western countries headed by the United States. Not only does the Rockets have no apology, but even NBA President Xiao Hua shows an indifferent attitude. This not only reflects their contempt and hostility towards us, but also reflects that China is indeed strong now, and has forced the other side to resist with a sinister trick. So, what is the root of our strength? Is it thought? Is it culture? What kind of spirit is it? In fact, all of them, but I believe that the reason that can best reflect China's strength is that our industrial strength has developed, and the material determines consciousness. The industry is strong and the country is truly powerful.

As the only country in the world with all industrial categories and sectors, we not only have ample labor, but also a broad market. In the current socialist construction, material and cultural accumulation is also a very important aspect. However, compared with the previous development methods at the expense of the environment and resources, after the guidance of the scientific development concept, we now focus on industrial production not only on weight, but also on quality. If we want to achieve this effect, then we will go The old road is obviously not very good. We should start with methods and efficiency. For a simple example, in industrial control, PLC is much more powerful than relay control.

What is PLC? It is a programmable logic controller, as its name suggests, it can be programmed. Because it is mainly used in industrial control, sometimes it will inevitably encounter changes in the content of the control project. If this is the case, switching to relay control will require a long time to return, not only is it time and effort, but the accompanying loss of money is even more difficult to estimate. And if you are using a PLC, then the problem is solved. You can realize the effective data collection and operation of the change control project by simply reorganizing the contents of various control projects through the corresponding PLC control programming software, such as OPENPCS. In addition, its small size, the number of installed lines is also relatively small. Therefore, it has the advantages that traditional relays can't match in terms of maintenance and installation and disassembly, which is beneficial to improve the working efficiency of control personnel and reduce various production costs.

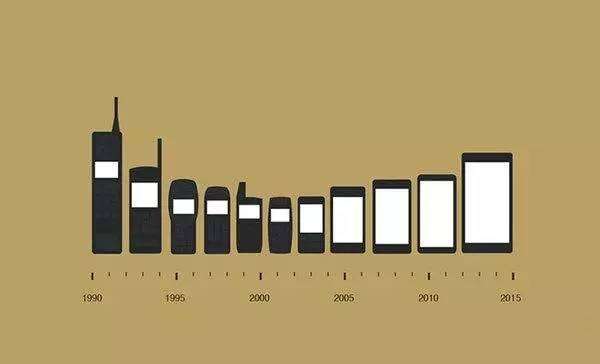

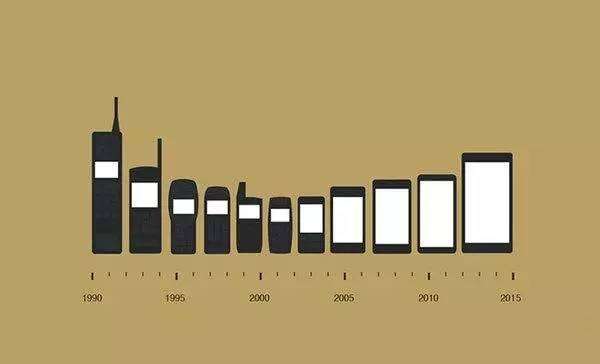

Whether you are holding a mobile phone or an office computer, you will find that its size has been greatly reduced compared to a long time ago, and the function is getting stronger and stronger. This is the progress of science and technology. In fact, PLC control equipment is also the same, when it was just invented, its size is not necessarily smaller than the relay control equipment. But as time progressed, it also became more and more slim. Many times, some devices called compact plc can complete complex types of industrial control projects with only one master module, several IO function modules and one terminal module. This is something that was previously unimaginable, but it has become a reality now. And the compact PLC equipment such as Shenyang Guangcheng Technology GCAN-400-PLC with its own CAN communication interface is the development direction of PLC equipment in the future. Let's take a brief look at it.

Shenyang Guangcheng Technology GCAN-400-PLC compact PLC equipment consists of a programmable main control module (GCAN-PLC-400), several GC series IO modules (GC-1008, GC-3804, etc.) and a terminal terminal module. composition. The GCAN-400-PLC compact PLC device main control module can be connected to all GC series IO modules. Users can choose to expand the IO module according to the actual needs of the site. The number of extended IO modules can reach 32. The GCAN-PLC-400 main control module supports automatic configuration. The user does not need to set parameters on the PC. The main control module will be automatically configured according to the front and rear positions of the inserted terminal module.

GCAN-400-PLC type compact PLC equipment

GCAN-400-PLC type compact PLC equipment

The GCAN-400-PLC compact PLC device can be programmed with OpenPCS software, which supports five standard programming languages according to the IEC-61131-3 standard, which makes the program highly portable and reusable. Moreover, the software also has a variety of debugging features (such as breakpoints, single step, monitoring, etc.), making the debugging program more convenient.

GCAN-400-PLC compact PLC equipment can not only complete various digital / analog input / output, but also integrate a variety of commonly used industrial fieldbus, such as: CAN bus, RS232/485 bus, Ethernet bus, and Support common communication protocols such as CANopen, ModbusRTU, ModbusTCP, etc. Users can easily realize function expansion and real-time communication by using these communication buses. If you would like to know more about the GCAN-400-PLC compact PLC device, please click on the link below or call the engineer to learn more: