Do you know the working principle of PLC?

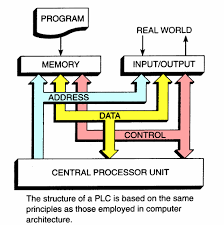

PLC takes the microprocessor as the core and has many features of the microcomputer, but the working principle of plc is very different from the microcomputer.

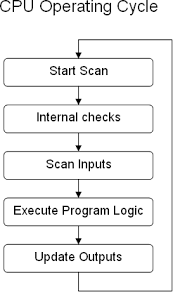

The microcomputer generally works by waiting for the command to work. The working principle of PLC is to work according to centralized input, centralized output and periodic cyclic scanning. The time taken for each cyclic scan is called a scan cycle.

Each program follows the working principle of PLC. The CPU starts execution from the first instruction, and executes the instructions one by one in sequence to perform periodic program loop scan. If there is no jump instruction, the user is executed sequentially from the first instruction. The program returns to the first instruction until the end, and so on and around.

In addition to executing the user program, the PLC also performs internal processing, input sampling, communication services, program execution, self-diagnosis, and output refresh in each scan work. The working principle of PLC consists of three parts, namely, power-on processing, scanning process and error processing. After the PLC is powered on, the CPU performs internal processing under the control of the system program, including hardware initialization, I/O module configuration check, and power-off retention range setting. And other initialization processing.

The working principle of PLC makes it have a strong self-diagnosis function. The PLC performs a self-diagnosis check every scan to determine whether the PLC's own actions are normal, such as power detection, internal hardware is normal, and the program syntax is wrong. According to the working principle of PLC, if an abnormality is detected, the LED and abnormal relay of the CPU panel will be turned on, and an error code will be stored in the special register; the CPU can signal according to the type and degree of the error, and even perform corresponding error processing to stop the PLC from scanning or forcing It becomes STOP state.

When the PLC is running normally, the length of the scan cycle depends on the length of the user application, the speed of the CPU, and the I/O point. According to the working principle of plc, the scanning time (usually 1-10ms/KB) is explained by the time required to execute the 1KB instruction. It is worth noting that the execution time of different instructions is different, so the scan time used for different instructions will be different. If you want to shorten the scan cycle for high-speed systems, you can consider both hardware and software. The remarkable features of the PLC cyclic cycle scanning mode are: high reliability and strong anti-interference ability, but the response is delayed and the speed is slow.

If you need more details about GCAN-PLC, click here: http://www1.gcanbox.com/

Email/skype: sygckj@gmail.com

Tel/whatsapp: +8613609896275

Facebook: https://www.facebook.com/gcanbox/

Buy it now: Click to buy on Alibaba

The microcomputer generally works by waiting for the command to work. The working principle of PLC is to work according to centralized input, centralized output and periodic cyclic scanning. The time taken for each cyclic scan is called a scan cycle.

Each program follows the working principle of PLC. The CPU starts execution from the first instruction, and executes the instructions one by one in sequence to perform periodic program loop scan. If there is no jump instruction, the user is executed sequentially from the first instruction. The program returns to the first instruction until the end, and so on and around.

In addition to executing the user program, the PLC also performs internal processing, input sampling, communication services, program execution, self-diagnosis, and output refresh in each scan work. The working principle of PLC consists of three parts, namely, power-on processing, scanning process and error processing. After the PLC is powered on, the CPU performs internal processing under the control of the system program, including hardware initialization, I/O module configuration check, and power-off retention range setting. And other initialization processing.

The working principle of PLC makes it have a strong self-diagnosis function. The PLC performs a self-diagnosis check every scan to determine whether the PLC's own actions are normal, such as power detection, internal hardware is normal, and the program syntax is wrong. According to the working principle of PLC, if an abnormality is detected, the LED and abnormal relay of the CPU panel will be turned on, and an error code will be stored in the special register; the CPU can signal according to the type and degree of the error, and even perform corresponding error processing to stop the PLC from scanning or forcing It becomes STOP state.

When the PLC is running normally, the length of the scan cycle depends on the length of the user application, the speed of the CPU, and the I/O point. According to the working principle of plc, the scanning time (usually 1-10ms/KB) is explained by the time required to execute the 1KB instruction. It is worth noting that the execution time of different instructions is different, so the scan time used for different instructions will be different. If you want to shorten the scan cycle for high-speed systems, you can consider both hardware and software. The remarkable features of the PLC cyclic cycle scanning mode are: high reliability and strong anti-interference ability, but the response is delayed and the speed is slow.

If you need more details about GCAN-PLC, click here: http://www1.gcanbox.com/

Email/skype: sygckj@gmail.com

Tel/whatsapp: +8613609896275

Facebook: https://www.facebook.com/gcanbox/

Buy it now: Click to buy on Alibaba