Micro-plc tools for embedded development advantages

When we are shopping, we usually pay attention to a vocabulary, that is, the price/performance ratio. In other words, we generally buy some things that the quality says in the past, and the price is relatively cheap, not necessarily the pursuit of the ultimate. Because the ultimate thing is often accompanied by expensive prices, which many people do not want to face. Through the case of cost performance, we can see that we have to consider many factors when dealing with and solving things, not just one aspect. When I was young, everyone learned about the board effect. It was a bucket of multiple planks. How much water it can hold depends on the length of the shortest plank. Of course, if some of the boards are too long, they look uncoordinated. Therefore, we need to balance all the factors, although not uniform, but try to make them have no obvious shortcomings. This theory is actually used for industrial control. Today, we will briefly compare the different advantages and disadvantages of embedded development and PLC control in industrial control.

Actual use scenario of PLC equipment

1. The same is for industrial control. In contrast, embedded development is more difficult to develop than PLC control. After all, it is a development method from scratch, all the requirements are seamless and very precise. In contrast, PLC control uses the corresponding programming software to change the different control content, although it can also complete the task, but the accuracy is certainly not as high as embedded development. This is the advantage of embedded development.

2, we take the first point to say that the way of embedded development is completely based on the needs of the current project, so it is limited. That is, it can only be used on this project. If you want to develop embedded development for another project, I am sorry, please start another stove and start over. In contrast, PLC control is not as accurate as embedded custom development, but it is flexible and can be used as long as you can understand its programming software. At this point, PLC is more popular with everyone.

3. Since embedded development is a work style from scratch, all structures and ideas are to be considered temporarily, so the time it takes is generally very long. PLC control can change its control content arbitrarily with the help of programming software. Many things can be called directly. Therefore, the preparation time of both parties is not at a level. If you encounter some very urgent work items, using PLC control is your best choice. Re-development with embedded software? You think too much.

In summary, PLC control and embedded development have their own advantages in the field of industrial control. We can't simply say which one is stronger than which one, but judge according to the specific situation. If the project preparation time is short, the control requirements are not so precise, and the project budget is relatively small, then the use of PLC is certainly not wrong. And if you don't have money, the project is not so urgent, and if the control accuracy is very high, then you should hurry to develop embedded! Just as we buy things to pursue cost-effectiveness, it is the best to meet our own needs.

Embedded development is more difficult

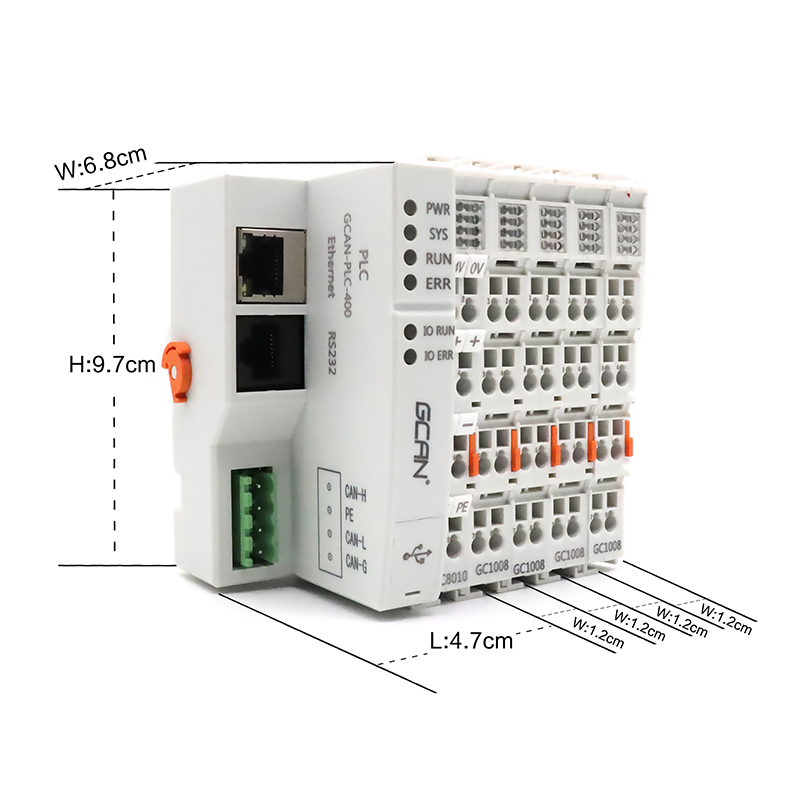

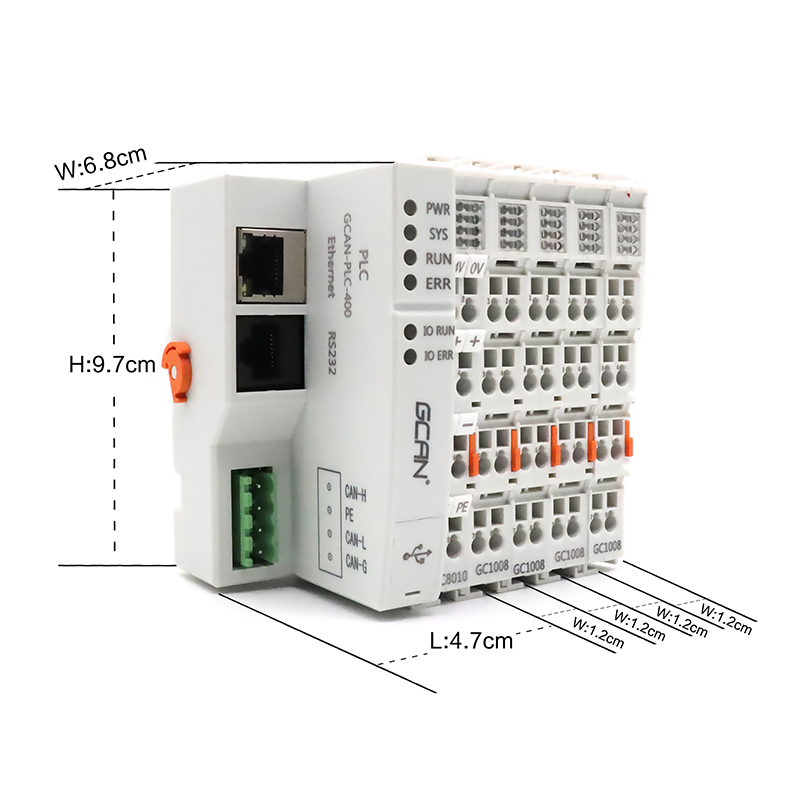

In order to better meet the project control needs of industrial control personnel, PLC equipment is also constantly evolving, and the current trend is micro-plc. The function is not reduced, the volume is reduced, and the carrying is more convenient. According to market needs, Shenyang Guangcheng Technology also launched the GCAN-PLC-400, a micro-plc device with independent intellectual property rights. Shenyang Guangcheng Technology GCAN-PLC-400 miniature plc is a bus module controller integrated with PLC function. It has the characteristics of compact shape and high cost performance. It can be used to connect CAN bus system, Modbus system and distributed bus terminal modules, and these terminal modules can be expanded by modular means.

GCAN-PLC-400 miniature plc

The GCAN-PLC-400 miniature plc consists of a programmable main control module (GCAN-PLC-400), several GC series IO modules (GC-1008, GC-3804, etc.) and a terminal terminal module. The GCAN-PLC-400 miniature plc main control module can be connected to all GC series IO modules. Users can choose to expand the IO module according to the actual needs of the site. The number of extended IO modules can reach 32. The GCAN-PLC-400 miniature plc main control module supports automatic configuration. The user does not need to set parameters on the PC. The main control module will be automatically configured according to the front and rear positions of the inserted terminal module.

The GCAN-PLC-400 miniature plc can be programmed using OpenPCS software, which supports five standard programming languages as specified in the IEC-61131-3 standard, which makes the program portable and reusable, and The software also has a variety of debugging features (such as breakpoints, single step, monitoring, etc.), making the debugging program more convenient

If you are interested, please click on the hyperlink to our Alibaba product page.

Also add my WhatsApp: +8615584249908