The application area of programmable logic controller plc

At present, PLCs have been widely used alll over the world in various industries such as metallurgy, petroleum, chemical, building materials, machinery manufacturing, electric power, automobile, light industry, environmental protection, culture and entertainment. With the continuous improvement of PLC performance and price ratio, the application area of programmable logic controller plc are constantly expanding. From the application type, the application of PLC can be roughly summarized into the following aspects:

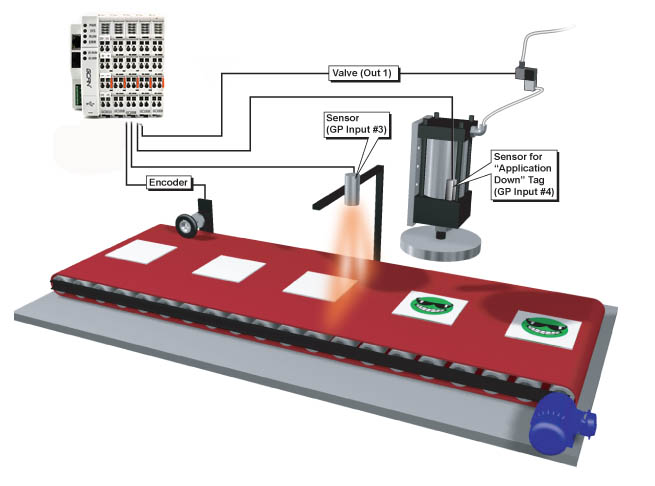

1. Switching logic control

The use of PLC's most basic logic operation, timing, counting and other functions to achieve logic control, can replace the traditional relay control, for stand-alone control, multi-group control, production automatic line control, etc., such as: machine tools, injection molding machines, printing machinery, assembly lines , electroplating lines and elevator control. This is the most basic application area of programmable logic controller plc as well as the most widely used application area of programmable logic controller plc.

2. Motion control

Most PLCs have single or multi-axis position control modules that drag stepper motors or servo motors. The application area of programmable logic controller plc is various mechanical equipment, such as motion control of various machine tools, assembly machines, robots, etc.

3. Process control

Large and medium-sized PLCs have multi-channel analog I/O modules and PID control functions, and some small PLCs such as GCAN-PLC also have analog input and output. Therefore, PLC can realize analog quantity control, and PLC with PID control function can form closed-loop control for process control. This is another application area of programmable logic controller plc in boilers, reactors, water treatment, brewing, and closed loop position control and speed control.

4. Data processing

This is the 4th application area of programmable logic controller plc. Modern PLCs have functions such as mathematical operations, data transfer, conversion, sorting, and table lookup. Data can be collected, analyzed, and processed. At the same time, these data can be transmitted to other intelligent devices through communication interfaces, such as computer numerical control (CNC). ) The device is processed.

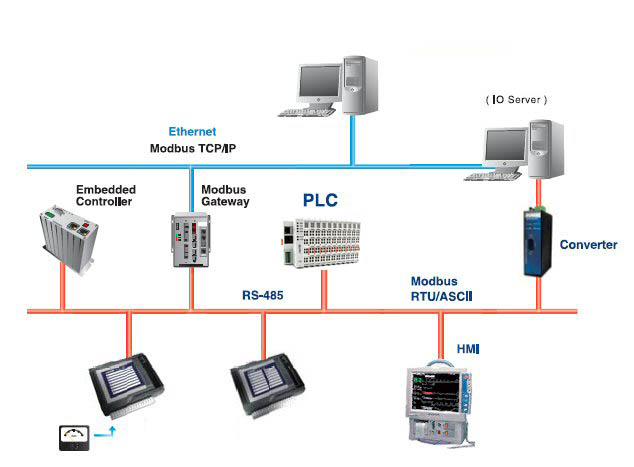

5. Communication networking

PLC communication includes communication between PLC and PLC, PLC and host computer, PLC and other intelligent devices. The application area of programmable logic controller plc also covers communication networking. PLC system and general computer can be connected to the network directly or through communication processing unit and communication conversion unit to realize information exchange. It can form a multi-level distributed control system with “centralized management and decentralized control” to meet the needs of the development of factory automation (FA) systems.

If you have any other questions or need more details about GCAN-PLC, please contact us right now.

Email/skype: sygckj@gmail.com

Tel/whatsapp: +8613609896275

Facebook: https://www.facebook.com/gcanbox/

Buy it now: Click to buy on Alibaba

1. Switching logic control

The use of PLC's most basic logic operation, timing, counting and other functions to achieve logic control, can replace the traditional relay control, for stand-alone control, multi-group control, production automatic line control, etc., such as: machine tools, injection molding machines, printing machinery, assembly lines , electroplating lines and elevator control. This is the most basic application area of programmable logic controller plc as well as the most widely used application area of programmable logic controller plc.

2. Motion control

Most PLCs have single or multi-axis position control modules that drag stepper motors or servo motors. The application area of programmable logic controller plc is various mechanical equipment, such as motion control of various machine tools, assembly machines, robots, etc.

3. Process control

Large and medium-sized PLCs have multi-channel analog I/O modules and PID control functions, and some small PLCs such as GCAN-PLC also have analog input and output. Therefore, PLC can realize analog quantity control, and PLC with PID control function can form closed-loop control for process control. This is another application area of programmable logic controller plc in boilers, reactors, water treatment, brewing, and closed loop position control and speed control.

4. Data processing

This is the 4th application area of programmable logic controller plc. Modern PLCs have functions such as mathematical operations, data transfer, conversion, sorting, and table lookup. Data can be collected, analyzed, and processed. At the same time, these data can be transmitted to other intelligent devices through communication interfaces, such as computer numerical control (CNC). ) The device is processed.

5. Communication networking

PLC communication includes communication between PLC and PLC, PLC and host computer, PLC and other intelligent devices. The application area of programmable logic controller plc also covers communication networking. PLC system and general computer can be connected to the network directly or through communication processing unit and communication conversion unit to realize information exchange. It can form a multi-level distributed control system with “centralized management and decentralized control” to meet the needs of the development of factory automation (FA) systems.

If you have any other questions or need more details about GCAN-PLC, please contact us right now.

Email/skype: sygckj@gmail.com

Tel/whatsapp: +8613609896275

Facebook: https://www.facebook.com/gcanbox/

Buy it now: Click to buy on Alibaba